Celotex is an industry-leading brand of insulation in the UK. They have over decades of experience in providing high-performance insulation. Celotex products are used in new builds, refurbishments and also as replacements for existing insulation. These insulation products are manufactured in the UK across various different production sites. This allows Celotex to offer a nationwide distribution service.

Showing 1–16 of 30 results

Celotex Insulation

Celotex provides a range of safe, reliable and high-quality insulation materials that are used to insulate countless homes and buildings all over the UK. Thousands of professionals choose Celotex to create environments that save energy every day. Insulation can help buildings reduce heat loss, which minimises the need for heating the building and therefore has less strain on the planet. In addition to this, Celotex manufactures its products with zero Ozone Depletion Potential. This is because they are environmentally conscious and provide innovative ways to help prevent global warming.

Builders love using Celotex as it is easy to install and cheap without sacrificing performance. Celotex saw its first big boost in popularity after WW2 when building materials were scarce. Since then, the products have improved and the brand has grown into the powerhouse that it is today. There are not many (if any) builders or property developers who have not heard of Celotex.

Most Celotex Insulation products are easy to cut to suit the application. In addition to this, Celotex installation is simple and can be achieved in multiple ways. The method of installation depends on the product or application. Please see our How to guides for a step by step guide on how to install. We suggest that you wear appropriate PPE and conduct risk assessments in order to minimise any potential health and safety risks.

Please see below for the range of Celotex products.

Celotex Multi Purpose PIR Insulation Boards

This category consists of TB4000, GA4000, XR4000 (PIR Multi-purpose Boards)

The thinnest product manufactured by Celotex is the TB4000. This insulation board is a high-performance, rigid polyisocyanurate (PIR) insulation board specifically designed to address thermal bridging and reduce localised heat losses.

TB4000 Celotex Insulation Board (20mm – 40mm)

The thinnest product manufactured by Celotex, TB4000 is a high performance, rigid polyisocyanurate (PIR) insulation board specifically designed to address thermal bridging and reduce localised heat losses.

It can be used throughout a building project to help maintain continuity of the insulation envelope and is suited to floor, wall and roof systems.

The Celotex TB4000 range is made up of many products. You can find the product codes below.

GA4000 Celotex Insulation Board (50mm – 100mm)

Designed for use throughout your building project, Celotex GA4000 is a versatile, high-performance, rigid polyisocyanurate (PIR) insulation board that's easy to handle and install. Suitable applications include:

- Ground floors whether solid concrete, block and beam, or suspended timber joist, and including where underfloor heating is used.

- Timber and steel-framed walls between and across the face of studs.

- Pitched roofs between and across the face of rafters.

- Flat roofs in ventilated cold roof constructions, installed from inside the building.

- Other retrofit and refurbishment projects lining existing timber and masonry structures to make them more thermally efficient.

The Celotex GA4000 range is made up of many products. You can find the product codes below.

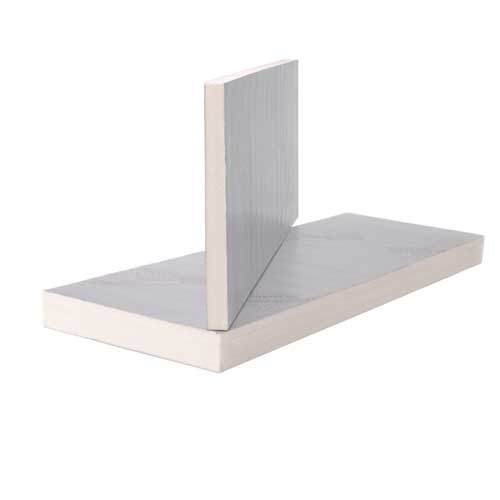

XR4000 Celotex Insulation Board (110mm – 200mm)

Unique and versatile, XR4000 is a high-performance, rigid polyisocyanurate (PIR) insulation board. Available up to 200mm thick, low U-values can be achieved without doubling-up insulation layers. Designed for use throughout your building project, it's easy to handle and install and suitable for applications.

The Celotex XR4000 range is made up of many products. This is the thickest range of Celotex Multi Purpose boards. You can find the product codes below.

Celotex Insulated Plasterboard

PL4000 Insulated Plasterboard

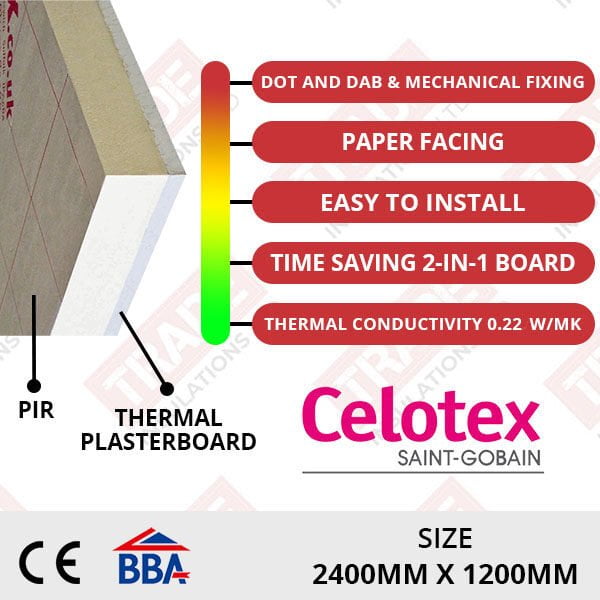

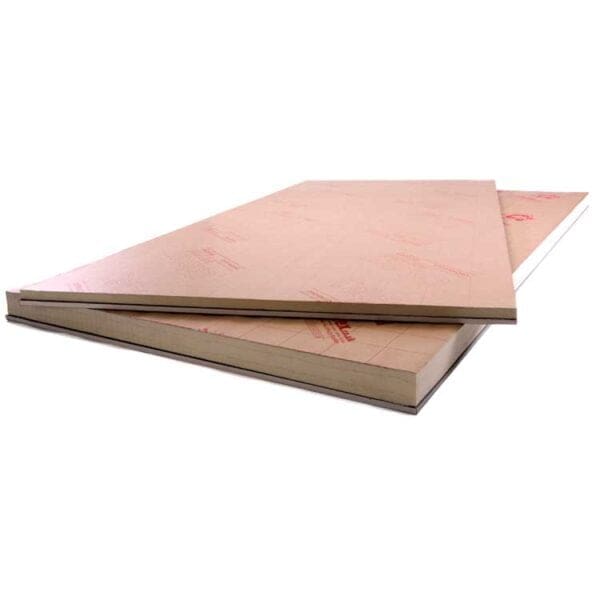

PL4000 is an innovative product, which merges PIR insulation with plasterboard. This can cut down install times as plasterboard and insulation is available in a single board. The polyisocyanurate (PIR) insulated board has a paper facing, and is laminated to a piece of 12.5mm tapered edge plasterboard. Sizes range from 25mm to 65mm. The PL4000 insulated plasterboard can be used for use in roofs as well as internal wall lining applications.

The thickness of the insulated plasterboard includes the 12.5mm plasterboard.

Features:

- This product can be installed by directly bonding (dot and dab) as well as and other fixed installation techniques.

- The tapered edge of the plasterboard means the installer has maximum flexibility and a speedy insulation.

- Can be used to improve the standards of the current building regulations.

- Keeps energy bills low long term and maximises savings.

- Can be a great product when refurbishing or for new build projects.

- Inbuilt vapour control layer

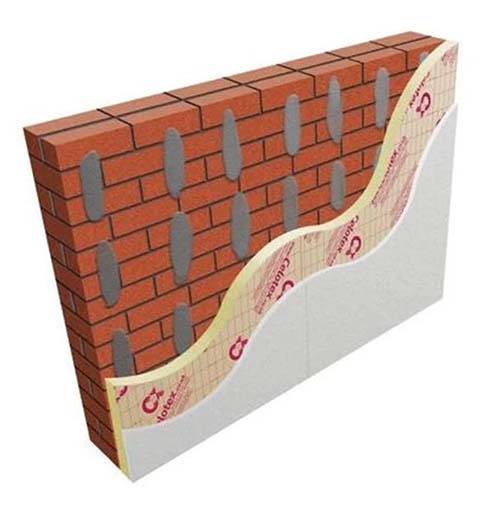

Celotex Cavity Wall Boards

CW4000 Cavity Insulation

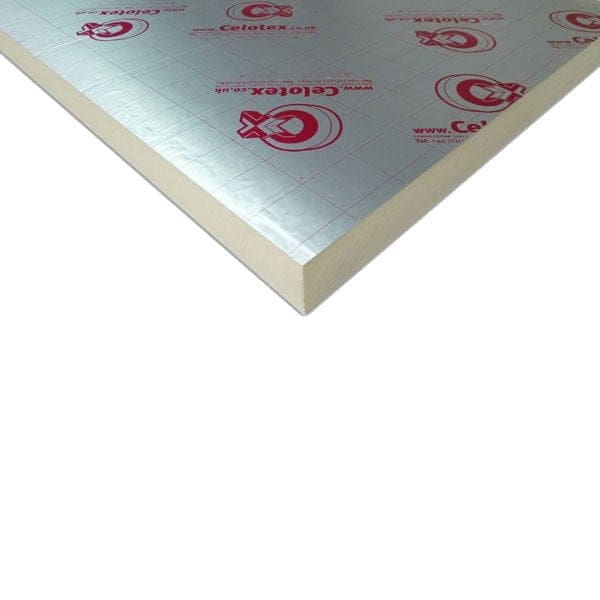

CW4000 is a polyisocyanurate (PIR) cavity insulation board with exceptional thermal performance with a low emissivity foil facing. The purpose of this cavity board is for cavity wall applications. It is one of the most popular cavity wall boards on the market. CW4000 sizes range from 50mm up to 100mm. These cavity wall boards can also be used for use in partial fill cavity wall applications.

Celotex Thermaclass 21

The Celotex Thermaclass Cavity Wall Board 21 is one of the newest additions to the family of Celotex products. It is designed for full fill masonry cavity wall applications. The core of the board features PIR with a low emissivity foil facing & uses tongue and groove edges. This facing is featured on each side to improve thermal performance. This popular new product is available in different thicknesses. These are Thermaclass 90mm, 115mm and 140mm.

Celotex Accreditations & Datasheets

- ISO 9001:2015 – quality management system criteria. All Celotex and ISOVER products are to 9001 standards.

- ISO 14001:2015 – environmental management system criteria. All products are to ISO 14001 standard.

- ISO 50001 – quality and environmental management standards. All products are to ISO 50001 standard.

- The British Board of Agreement (BBA) – verify that products are compliant with the relevant Building Regulations.

- The CE marking – is a confirmation that products are sold in the European Economic Area and meet the criteria. All products have CE approvals.

- The European Certification Board – provides information related to their non-classification under the European regulation. The EUCEB certificate shows that mineral wool is bio-soluble and meets the standard.

- Indoor Air Comfort Gold certification – ensures that low product emission requirements are met. The manufactured ISOVER UK structural building meet achieves Eurofins ‘Gold’ standard for indoor air quality.

- BES – organisational governance, supply chain management, environmental and social aspects that must be met in order to ensure the responsible sourcing of construction products. Isover UK manufactured glass mineral wool insulation achieves BES 6001.

Please see below a full list of all Celotex datasheets. These datasheets feature useful information on Celotex products. We ensure that all datasheets are updated when possible. This is so we can provide the most up-to-date datasheet to reflect the Celotex products listed on our website. The Celotex datasheets have come directly from Saint Gobain, who own the rights to the Celotex brand.

Celotex TB4000 Datasheet

Celotex GA4000 Datasheet

Celotex XR4000 Datasheet

BBA Certfication – Timber Frame (Celotex PIR)

BBA Certfication – Floors (TB4000, GA4000, XR4000)

BBA Certfication – Pitched Roofs (Celotex PIR)

BBA Certfication – Dry Lining (TB4000, GA4000, XR4000)

At Trade Insulations, you will find all Celotex Insulation on our website. We always offer our best price and always go above and beyond for our customers. When you place an order, we get in contact with you to confirm your delivery on a suitable date. As an approved supplier, we are able to offer trade prices to the public.