MF Ceiling

On our website you can find all MF ceiling components. We stock all the items you need to build metal frame ceiling systems. You can find products such as top hats (MF5), perimeter channels (MF6A), primary channels (MF7) as well as connecting clips. (MF9). Plasterboards can be easily fixed to the built metal grid systems to create a flat surface. The space between a structural ceiling and an MF ceiling is often used to hide electrical wiring, HVAC ducts and also plumbing.

Showing all 5 results

MF Ceiling Systems

A MF ceiling system is also known as a metal frame ceiling system. They typically comprise of metal main runners, cross tees, and perimeter channels. A built system combines the strength and structure of metal with the versatility and aesthetics of plasterboard. MF ceiling systems are popular are they are quick and easy to build. In addition to this, they are suited to both new build and refurb projects. Furthermore, MF ceiling systems can be adapted to fit your specification.

A typical MF (metal frame) ceiling system includes these products:

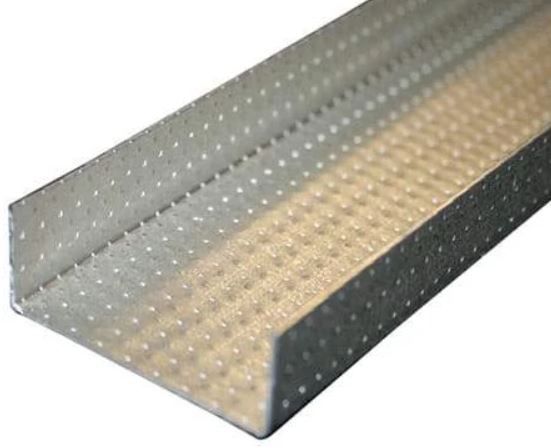

- MF6A (Perimeter Channel)

- MF5 (Top Hat)

- MF7 (Primary Channel)

- MF9 (Metal Furring Clips)

Metal frame angles can be cut down to a required size and therefore are adaptable. In addition to this, MF Systems can be found in both commercial and residential settings. It is common to find MF ceiling systems in cinemas, hospitals, restaurants and offices.

What are the benefits of using a metal frame ceiling system?

There are many benefits to building a metal frame ceiling system. Below are some of the benefits that make MF ceiling systems so popular.

Easy to adapt and build

MF Ceiling systems can be built with ease. They also are adaptable, which makes them perfect for a wide range of projects. The ease of installation can reduce construction times. They can also be designed for easy access to concealed areas.

They look great

A finished system combined with plasterboard can provide a smooth flat surface to improve the aesthetics of the room. They can also be modified to match the interior of a building. This consistency in design can really make a room 'come alive'

You can use them to conceal areas

One of the biggest benefits is that an MF ceiling system creates space between the ceiling structure and the MF ceiling. This allows for the concealment of components such as wiring. The concealment of pipes, ducts and wires can keep the area looking neat and tidy.

They can be used to improve acoustic performance

MF ceiling systems can reduce noise transmission. This is ideal in settings such as cinemas and schools. Products such as Knauf Soundshield Plus are an acoustic plasterboard that is ideal whereby acoustic performance is essential.

They can be used to improve thermal performance

The extra layer below the structural ceiling can help improve the thermal performance of a property. This can help achieve a more comfortable interior temperature

MF Ceiling systems can offer fire protection

Metal framing in combination with fire rated plasterboard are ideal in slowing down the spread of flame. This makes them an excellent choice. The properties of all components can provide additional fire protection.

They are durable

Metal frame systems are durable and can benefit from moisture resistance. This durability ensures they maintain structure whilst offering protection from other factors such as termites.

What types of plasterboard should I use with a MF ceiling system?

The type of plasterboard used is dependant on the specification of a project. Whether it be standard wall board, acoustic plasterboard or even fire rated plasterboard – they should all be compatible with metal frame ceiling systems. All of the products on our website feature data sheets and technical specifications. These are directly from the manufacturer. We always advise that you read through these to ensure compatibility.