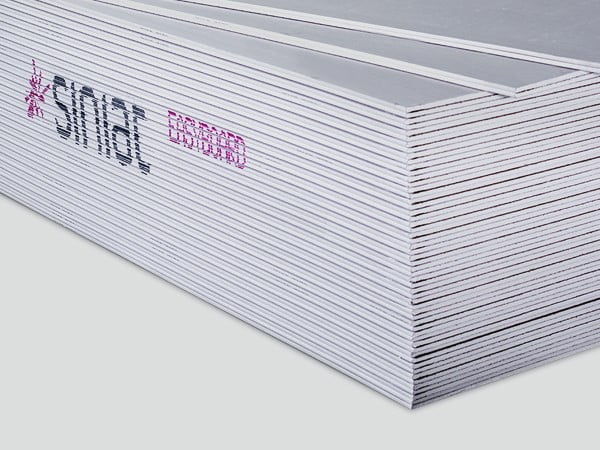

12.5mm Siniat Plasterboard 3000mm x 1200mm

12.5mm Siniat Standard GTEC Board is a high-quality plasterboard product that offers excellent strength and durability, making it an ideal solution for interior drylining projects. This versatile board can be used for a wide range of applications, including partition walls, ceilings, and linings for walls and columns.Made from high-quality gypsum plaster and reinforced with glass fibre, the 12.5mm Siniat Standard GTEC Board offers superior strength and resistance to cracking and impact damage.

The benefits of using 12.5mm Siniat Standard GTEC Board

The 12.5mm Siniat Standard GTEC Board offers many benefits for interior drylining projects. Its high-quality gypsum plaster construction, reinforced with glass fibre, ensures strength and resistance to cracking and impact damage. This makes it a practical choice for high traffic areas. The board is also easy to install and can be cut to size with minimal effort. Its smooth surface allows for a wide range of decorative finishes, such as painting, wallpapering, or tiling.

How to install 12.5mm Siniat Standard GTEC Board

Installing the Siniat Standard GTEC Board is a straightforward process that can be completed with minimal effort. Follow these simple steps to ensure a successful installation:

- Measure the area:

- Cut the board:

- Fix the board:

- Tape the joints:

- Apply jointing compound:

- Sand the surface:

- Finish the surface:

Start by measuring the area where you will be installing the board. This will help you determine how many boards you will need and what size they should be.

Using a utility knife or handsaw, cut the board to the desired size. Be sure to use a straight edge for a clean cut.

Fix the board to the surface using screws or nails. The board should be fixed at regular intervals, typically every 150mm, to ensure a secure hold. In addition to this, plasterboard can be fitted using the dot and dab technique.

Once the board is fixed, use jointing tape to cover the joints between the boards. This will help to create a smooth surface and prevent cracking.

Apply jointing compound over the jointing tape using a trowel. Smooth the compound out to create a flat surface.

Once the jointing compound is dry, sand the surface using fine sandpaper. This will create a smooth surface ready for painting, wallpapering, or tiling.

Apply the desired finish to the surface, such as paint, wallpaper, or tiles. This will create a finished surface that is both functional and aesthetically pleasing.

By following these simple steps, you can install the Siniat Standard GTEC Board quickly and easily, creating a high-quality finished product that is both strong and durable.

How to correctly store Siniat Standard GTEC Board

Proper storage of the Siniat Standard GTEC Board is essential to ensure its quality and performance. Follow these guidelines to store the board correctly:

Store the board indoors: The board should be stored in a dry, indoor environment, away from direct sunlight and moisture. This will help to prevent warping or damage to the board.

Store the board flat: The board should be stored flat on a clean, level surface. This will help to prevent any bowing or warping of the board.

Avoid stacking too high: When stacking the board, avoid stacking it too high, as this can cause the bottom boards to become compressed and damaged.

Protect the edges: To prevent damage to the edges of the board, stack it with the long edges facing upwards, and place a protective sheet of material, such as cardboard or foam, between each board.

Store for a limited time: The board should only be stored for a limited time, typically no longer than three months. This will help to ensure that the board remains in good condition and ready for use when needed.

By following these guidelines, you can ensure that the Siniat Standard GTEC Board is stored correctly, preserving its quality and ensuring that it is ready for use when needed.

What is the Siniat Standard GTEC Board made of?

The Siniat Standard GTEC Board is made of high-quality gypsum plaster, reinforced with glass fibre.

What finishes can be applied to the Siniat Standard GTEC Board?

The board can be finished with a wide range of decorative finishes, such as painting, wallpapering, or tiling.

Is the Siniat Standard GTEC Board sustainable?

Yes, the board is made from natural gypsum, a plentiful and sustainable material. Its manufacturing process is also energy-efficient, reducing its impact on the environment.

How is the Siniat Standard GTEC Board installed?

The board can be easily installed by measuring and cutting it to size, fixing it to the surface using screws or nails, taping the joints, applying jointing compound, sanding the surface, and finishing it with the desired decorative finish.

How should the Siniat Standard GTEC Board be stored?

The board should be stored indoors in a dry environment, stored flat on a clean, level surface, and stacked with the long edges facing upwards and protected by a sheet of material between each board.

| Dimensions | 3000 × 1200 mm |

|---|---|

| Brand | Siniat |

| Thickness | 12.5mm |

| Material Type | Gypsum |

| Pieces Per Pack | 1 |

| Sales Unit | Board |

| Unit Coverage | 3.6m2 |

| Manufacturers Reference | 90623 |

| Thermal Conductivity | 0.19W/mK |

| Fire Rating | A2-s1, d0 |

| Edge Type | Tapered |

| Facing | White Paper Facing |

| Weight (kg/m2) | 8.4kg/m2 |

| Product Range | Siniat GTEC Standard Plasterboard |

Logan –

Made my DIY project a success. These plasterboards provided a professional finish