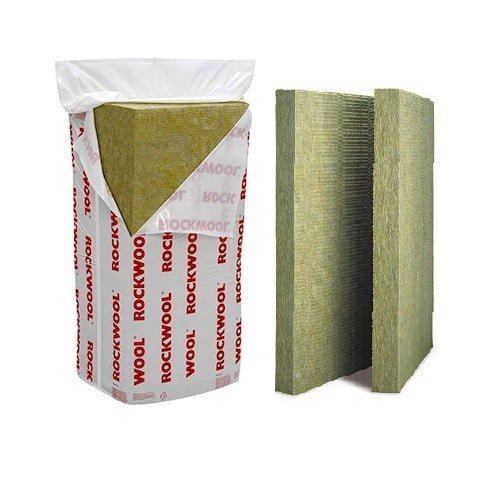

150mm Dritherm Cavity Slab 32

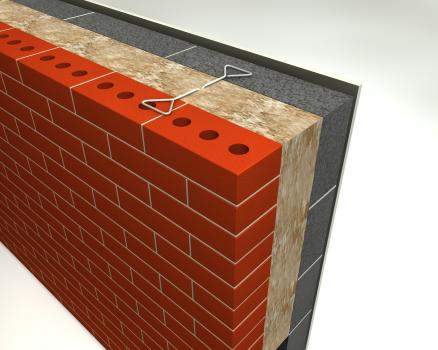

150mm Dritherm Slab 32 is a high-performance insulation solution for residential and commercial buildings. It is designed to provide excellent thermal and acoustic insulation for cavity walls.

This product is made of highly resilient and non-combustible mineral wool material. The wool is manufactured from a blend of naturally occurring rock and recycled glass, which makes it an environmentally friendly choice. 150mm Dritherm 32 is designed for use in cavity walls.

The Benefits of using Knauf 150mm Dritherm 32

One of the key benefits of this product is its excellent thermal performance. It has a thermal conductivity of 0.032 W/mK, which means it can provide high levels of insulation and help reduce energy consumption. This makes it ideal for use in both new and existing buildings that require insulation upgrades.

Another benefit of Knauf Dritherm 150mm Cavity Slab 32 is its acoustic performance. It has a high-density structure that can effectively absorb sound waves and reduce noise transmission. This makes it an excellent choice for buildings located in noisy areas or those that require a quiet environment, such as hospitals or schools.

This product is also easy to install. It comes in pre-cut sizes that fit perfectly into standard cavity walls. The slabs are designed to be friction-fitted, which means they can be easily pushed into place without the need for any adhesive or mechanical fasteners. This makes installation quick and hassle-free, saving time and reducing labour costs.

Knauf Dritherm 32 150mm is a safe and durable insulation solution. It is non-combustible, which means it does not contribute to the spread of fire. It is also resistant to moisture, which means it will not sag or slump over time. This ensures that it maintains its thermal and acoustic performance for the lifetime of the building.

In addition, Knauf 150mm Dritherm 32 is environmentally friendly. The product is manufactured using sustainable materials and has a low environmental impact. It is also recyclable, which means it can be reused at the end of its life cycle.

Installing 150mm Knauf Dritherm Cavity Slab 32

Installing 150mm Knauf Dritherm Ultimate Cavity Slab 32 is a straightforward process that can be carried out by a competent DIY enthusiast or a professional contractor. Here are the general steps involved:

- Preparation:

- Cutting the insulation:

- Installing the insulation:

- Finishing:

Before installing the insulation, it’s essential to ensure that the cavity wall is clean and free from any debris or protrusions that could affect the insulation’s performance. Any existing insulation should be removed to make way for the new installation.

Knauf Dritherm Ultimate Cavity Slab 32 – 150mm comes in pre-cut sizes that fit standard cavity walls. However, if necessary, the insulation can be cut using a sharp knife or saw to fit any irregular spaces.

The insulation is designed to be friction-fitted into the cavity wall. Start by placing the insulation at the bottom of the cavity, ensuring that it fits snugly. Then work your way up, filling the cavity with insulation until it is completely filled. Ensure that the insulation is flush with the surface of the inner leaf.

Once the insulation is installed, it’s important to ensure that the cavity is sealed to prevent any air leakage. Seal any gaps or holes with a suitable sealant or tape. Finally, replace any removed skirting boards or architraves.

It’s worth noting that proper safety precautions should be taken when handling insulation, including wearing protective clothing, gloves, and goggles. If you’re not confident in carrying out the installation yourself, it’s best to hire a professional contractor to ensure that the insulation is installed correctly and safely.

Correctly storing 150mm Dritherm 32

Proper storage of Knauf Dritherm Ultimate Cavity Slab 32 (150mm) is essential to maintain its quality and performance. Here are some tips on how to store the insulation correctly:

Store the insulation in a dry and secure location: Moisture can affect the insulation’s performance and cause it to sag or slump over time. Therefore, it’s important to store the insulation in a dry location away from any potential sources of moisture. The storage area should also be secure to prevent any damage or theft.

Keep the insulation off the ground: To avoid any potential moisture damage, store the insulation off the ground on pallets or racks. This will also make it easier to access and transport the insulation when needed.

Protect the insulation from sunlight and weather: Exposure to sunlight and weather can also affect the insulation’s performance. Therefore, it’s important to cover the insulation with a tarpaulin or plastic sheeting to protect it from the elements.

Avoid stacking heavy objects on top of the insulation: 150mm Knauf Dritherm Ultimate Cavity Slab 32 is designed to be resilient and durable. However, stacking heavy objects on top of the insulation can cause it to compress, affecting its performance.

Store the insulation in its original packaging: Knauf Dritherm Cavity Slab 32 (150mm) is typically supplied in polythene packaging that protects it during transit and storage. It’s important to keep the insulation in its original packaging until it’s ready to be installed to ensure that it stays clean and protected.

What is Knauf Dritherm Ultimate Cavity Slab 32?

Knauf Dritherm Ultimate Cavity Slab 32 – 150mm is a high-performance insulation product designed for use in external masonry cavity walls. It is made from mineral wool and has excellent thermal and acoustic insulation properties.

How do I install Knauf Dritherm Ultimate Cavity Slab 32?

Knauf Dritherm Ultimate Cavity Slab 32 should be installed between the two leaves of a cavity wall, ensuring a tight fit to prevent air gaps. It can be friction fitted or mechanically fixed using wire or plastic retaining clips.

What are the benefits of using Knauf Dritherm Ultimate Cavity Slab 32?

Knauf Dritherm Ultimate Cavity Slab 32 provides excellent thermal and acoustic insulation, helping to reduce energy costs and noise pollution. It is also fire resistant and water repellent, making it a safe and durable choice for cavity wall insulation.

Is it environmentally friendly?

It is made from recycled materials and is fully recyclable at the end of its life. It also has a low embodied energy, meaning that it requires less energy to manufacture and transport than many other insulation products.

Is it suitable for use in all types of buildings?

Knauf Dritherm Ultimate Cavity Slab 32 (150mm) is suitable for use in most types of buildings, including residential, commercial, and industrial properties. However, it may not be suitable for use in buildings with unusual or complex wall constructions, so it is always best to consult with a qualified installer.

| Dimensions | 1200 × 455 mm |

|---|---|

| Brand | Knauf |

| Thickness | 150mm |

| Material Type | Glass Mineral |

| Pieces Per Pack | 4 |

| Sales Unit | Pack |

| Unit Coverage | 2.18m2 |

| Manufacturers Reference | 580216 |

| Thermal Conductivity | 0.032W/mK |

| Density | 27kg/m3 |

| Fire Rating | A1 Non-Combustible |

| Edge Type | Square |

| Facing | Glass Mineral Wool |

| Weight (kg/m2) | 4.05kg/m2 |

| Product Range | Knauf Dritherm 32 Cavity Slabs |

Zachary –

Knauf slabs are always reliable

Cole –

still need a few more packs, but really usefull / Trade Insulations is my one stop shop for Insulation now

Dawn Callons –

Really compact so they didn’t take up too much room.

Andrew Laskawaki –

Arrived on site packed well