Kingspan Insulation is owned by the Kingspan Group. The Kingspan group is a family business that was founded in 1965 in Ireland. In Kingspan’s beginning, they were manufacturing wheelbarrows. It was only when Kingspan’s founder, Eugene Murtagh, saw an opportunity with roof panels and rigid insulation, which has continued to grow to this day. The Kingspan group has grown to become one of the most well-known providers of insulation products. They are renown for their excellent quality and high-performance results. Kingspan is also committed to making a difference to the environment and tackling climate change.

Kingspan operate in over 70 countries around the world and boast over 120 manufacturing sites. Get the best price on Kingspan when you purchase directly from us. Below you can see the different categories of Kingspan Insulation.

Showing 1–16 of 140 results

Kingspan Insulation

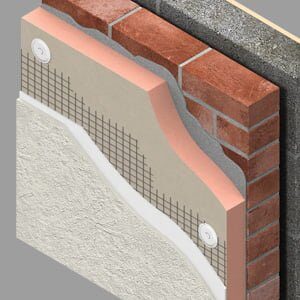

Kingspan insulation provide insulations products for the construction industry. They offer a wide range of product types. Kingspan insulation have solutions for insulating walls, roofs, floors, and lofts. Their high performance insulation products are easy to install and boast a range of features. Kingspan's popular PIR range is called the 'Therma' range and features TP10 Thermapitch (General Purpose / Pitched Roof Insulation), TF70 Thermafloor (Floor Insulation), TW55 Thermawall (Wall Insulation) and TW50 Cavity Thermawall (Cavity Wall Insulation). These PIR products are technically the same but are branded different by Kingspan. They are available in different thicknesses to suit almost all applications.

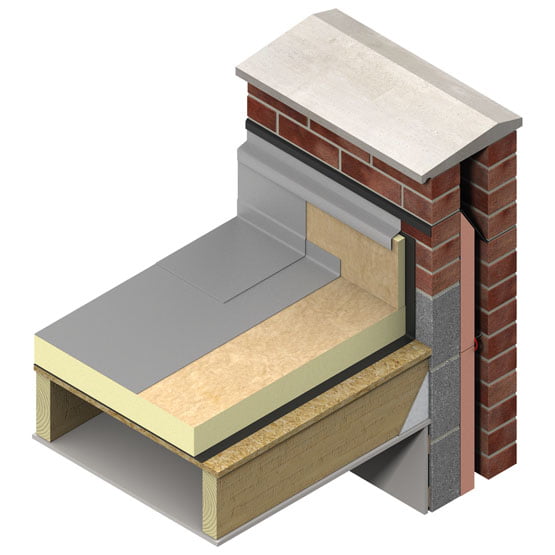

Kingspan have Thermaroof products, which are different in specification and are suited for flat roof applications. Kingspan TR27 Thermaroof is compatible with green roof systems and most bitumen and mastic asphalt waterproofing systems. The Kingspan TR24 Thermaroof is suitable for new builds and refurbishments and has a thermal conductivity of 0.024 – 0.027 W/mK. Furthermore, it is compatible with the majority of torch applied waterproofing systems. Finally, the Kingspan TR26 boasts a thermal conductivity of 0.022 W/mK. It is also compatible with green roof systems as well as most mechanically fixed single-ply waterproofing systems. The Kingspan TR26 is among the most thermal efficient insulation solutions for flat roofs.

One of the new product ranges from Kingspan is the Kingspan Greenguard Insulation. The Greenguard range is for specialist installs such as heavy duty flooring, inverted roofs and car parks. It features 3 seperate products within the Greenguard range. These include Greenguard GG300, Greenguard GG500 and Greenguard GG700. The numbers after the 'GG' correspond to the compression strength of the product. For example GG500 has a compressive strength of 500 kPa.

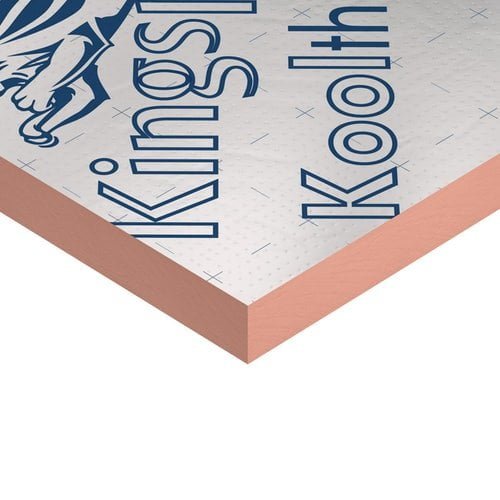

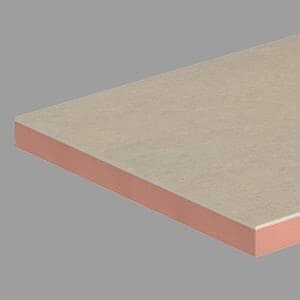

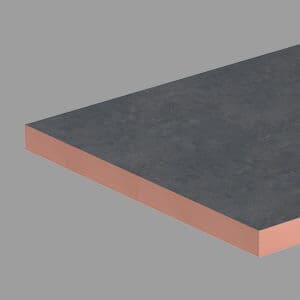

Lastly, one of Kingspan's most popular product range is the Kingspan Kooltherm range. These are thermoset phenolic insulation boards.

What is Kingspan Kooltherm?

Kingspan Kooltherm differs from the other ranges from Kingspan. This is because Kingspan Kooltherm products uniquely feature a phenolic core. Kingspan's thermoset phenolic insulation boards are high performance and suitable for a range of applications. You can identify a Kingspan Kooltherm product by its product code. If it starts with a 'K' then it is a part of the Kingspan Kooltherm range. The Kingspan K103 Floor boards are insulation boards designed for flooring. Kingspan K118 is an insulated plasterboard, which combines plasterboard with insulation. The finished result is a 2 in 1 product that is easy and quick install. In addition to this, Kingspan also have a Kingspan K5 external wall board.

Kingspan Kooltherm features cavity wall boards (K108 and K106). The difference between the K106 and K108 cavity boards is that the K108 cavity wall boards are a partial fill cavity wall board whereas Kingspan K106 is a full fill cavity wall board.

Other products in the Kingspan range include the Kingspan K107 insulation boards, which are designed for pitched roof installations. Another Kooltherm product is the K110 Soffit boards, which also includes the K110 Soffit Plus boards. The K110 Plus board glass tissue facing on one side as well as a 6mm build board fixed to the opposite side.

Overall, the Kingspan Kooltherm phenolic range is very in demand amongst builders and developers. This is likely due to its high performance and unique phenolic core.

What is phenolic insulation?

The Kooltherm range features a phenolic core, however you maybe wondering what is phenolic insulation? In short, phenolic insulation is a type of thermal insulation that is constructed from phenolic foam. Phenolic foam is a material produced from a mixture of phenol, a type of resin, and other chemicals. This mixture is then subjected to heat, causing it to expand and form a rigid foam.

Phenolic insulation offers several advantages. It has a very low thermal conductivity, meaning that it is very effective at reducing the transfer of heat. This makes it a popular choice for insulating buildings to improve energy efficiency.

Below we have listed the full phenolic Kooltherm range below:

Where is Kingspan manufactured?

The Kingspan headquarters are based in Ireland, however they have many manufacturing facilities all over the world. Kingspan is sold and used in over 70 countries. In total, there are over 120 Kingspan manufacturing factories. In the UK, Kingspan have factories in England, Scotland, Wales as well as Ireland. In addition to this, Kingspan is manufactured in other countries such as the United States, Germany, Australia and China.

In just the United States alone, there are facilities located in these locations:

- Atlanta, Georgia

- Columbus, Ohio

- DeLand, Florida

- Lake Forest, Illinois

- Marietta, Georgia

- Modesto, California

- Santa Ana, California

- Stamford, Connecticut

- Terrell, Texas

Kingspan insulation is used and trusted by many builders and developers across the globe. Furthermore, there are Kingspan offices located in many different countries.

At Trade Insulations, we offer our best price on Kingspan insulation. We are dedicated to offering top brands such as Kingspan at trade prices. The best part is, you don't even need to be in the trade to benefit.

How to cut Kingspan?

There will often be scenarios in which you may have to cut Kingspan boards down to the size you need. Kingspan boards such as TP10 can easily be cut by following the steps below.

- Measure and mark the Kingspan board using a straight edge and a pencil or marker. Make sure that the markings are precise and accurate.

- Put on protective equipment such as safety glasses and a dust mask to protect yourself from any dust or debris that may be created during the cutting process.

- Using a sharp utility knife or saw, cut the Kingspan Insulation board along the marked lines. Apply firm, steady pressure to ensure a clean and accurate cut.

- Continue cutting the Kingspan Insulation board until you have the size you need. Make sure that the edges are straight and smooth.

How to install Kingspan Insulation?

The installation of Kingspan insulation is dependant on the product and application type. For example, the install of Kingspan TR24 will differ from the install of TW55 as TR24 is specifically designed for flat roof applications. On our website, we provide full datasheets as well as information to help with installation on our product pages. Often this will be guidance from Kingspan themselves. A big advantage to using Kingspan insulation is that it is designed to be easy to install.

If you are new to installing Kingspan (or board insulation in general) then we always suggest that you consult a professional for advice.

If you want more information about the install of other products, we suggest visiting the product pages as these will be able to provide you with more in depth instructions based upon the product you are viewing.

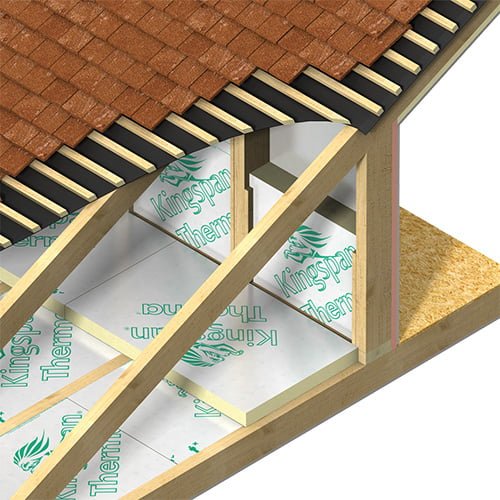

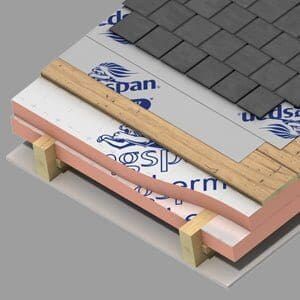

Below we offer basic guidance on how to install Kingspan insulation between rafters. This refers to the installation of K107. The also features a tutorial video from Kingspan.

how to install Kingspan Insulation between rafters?

Certain Kingspan Insulation products are specifically designed to be installed between rafters. For example, Kingspan K107 is a pitched roof board, which is a full fill insulation product that can be applied between and under rafters in a pitched roof.

When installing insulation at rafter level, it is important to wear appropriate protective gear, including gloves and a mask to prevent inhalation of any insulation particles when cutting the boards.

It is also important to follow all manufacturer instructions for the specific type of insulation you are using, to ensure proper installation and maximum effectiveness. The following video shows how you can install Kingspan Insulation between rafters. This video has been produced by the Kingspan Insulation group.

Do I need a vapour barrier with Kingspan?

A vapour barrier is a material used in building construction to prevent moisture vapour from penetrating through walls, ceilings, and floors. It is typically a sheet of material that is impermeable to water vapour, such as plastic or foil, and is installed on the warm side of insulation in a building assembly. The purpose of a vapour barrier is to control the flow of moisture vapour and prevent it from condensing inside walls or other building materials, which can lead to mould, rot, and other moisture-related problems.

A common question asked is if you need a vapour barrier with Kingspan K118. Most often you do not need a vapour barrier with Kingspan K118. This is because Kingspan K118 comes equipped with a integral Vapour Control Layer, which is otherwise known as a VCL. The purpose of a VCL is to protect insulation from moisture. In addition to this, it can also protect insulation from wet screeds. Vapour Control Layers are essential for both new and existing builds. We always recommended that you consult an architect or building professional when purchasing Kingspan Insulation to ensure you have the most suitable product for your project.

What is Kingspan Planet Passionate?

Planet Passionate is Kingspan's global sustainability program. It was launched in 2019 and is aimed at significantly reducing the environmental impact of Kingspan's business operations and products over a ten-year period.

The Planet Passionate program is structured around four main areas: energy, carbon, circularity, and water. The program includes a range of targets and commitments that Kingspan has set for itself in these areas. These include commitments to:

- Achieve net-zero energy across all Kingspan sites by 2020, and match 100% of the company's operational energy usage with renewable energy

- Reduce the company's carbon emissions by a significant amount

- Upcycle billions of PET bottles in Kingspan insulation products

- Harvest rainwater for use in Kingspan's manufacturing processes.

In addition to this, Kingspan's insulation products, also contribute to sustainability by improving the energy efficiency of buildings. Well-insulated buildings require less energy for heating and cooling, which can reduce the carbon footprint of the building over its lifetime. Kingspan is dedicated to improving their product range and processes by creating innovative ways to become more sustainable.

Kingspan is currently owned by various different shareholders, however the companies founder Eugene Murtagh owns roughly 16% of the business. Eugene Murtagh was the CEO of Kingspan Insulation up until 2005 when his son Gene Murtagh took over the role.

Kingspan U Value Calculator

U-value refers to the measure of thermal transmittance or heat transfer through a particular material or assembly. It is a metric used to quantify the rate of heat loss or gain across a structure or building component.

The U-value is expressed in units of watts per square meter per degree Celsius (W/m²°C) or British thermal units per hour per square foot per degree Fahrenheit. A lower U-value indicates better insulation performance, as it means less heat transfer occurs through the material or assembly.

By controlling the U-value of insulation materials, such as walls, roofs, windows, or doors, it is possible to enhance energy efficiency in buildings by reducing heat loss during colder seasons or minimising heat gain in warmer climates.

The Kingspan website features a U Value Calculator.The U-value calculator a helpful tool for determining the U-value of insulation boards based on specific applications and product types. This calculator allows builders, architects, and individuals involved in construction to assess and compare the thermal performance of different insulation materials and make informed decisions about their use in building projects.

Cheap Kingspan

We offer cheap Kingspan insulation available to purchase on our website. All of the Kingspan products that we sell are brand new and never seconds. At Trade Insulations, we are the home of cheap Kingspan, which can be purchased in minutes on our website. Our easy to use website and extensive product range ensures that you don't need to go anywhere else for all of your insulation needs. Our website has a secure checkout and we boast many 5 star reviews from our loyal customers. Join the thousands of people who use Trade Insulations and get your Kingspan insulation delivered directly to your site / home.