We stock Rockwool products on our website. ROCKWOOL Limited is part of the ROCKWOOL Group. Rockwool was founded in 1909 and is a Danish manufacturer with headquarters in Denmark. Rockwool is a leading manufacturer of mineral wool and insulation materials. Rockwool is the second-largest maker of insulation materials and continues to grow. They have one factory in Bridgend, South Wales, and over 500 employees across the UK. Rockwool also has businesses in over 39 countries and a very large number of employees.

Showing 1–16 of 51 results

Rockwool is committed to manufacturing products in a sustainable way. They aim to continuously make changes to meet and improve sustainability from energy consumption to noise pollution and fire resilience.

How are sustainability future goals?

- Reduce CO2 emission intensity from stone wool production facilities by 20% by 2030.

- Reduce energy consumption within their own offices by 75% by 2030.

- Increase the number of countries where we offer recycling services for our products by 30% by 2030.

- Reduce lost time incident rate by 10% and ensure 0 fatalities annually.

- Reduce water intensity within manufacturing facilities by 20% by 2030.

- Reduce landfill waste from manufacturing facilities by 85% by 2030.

What Is Rockwool?

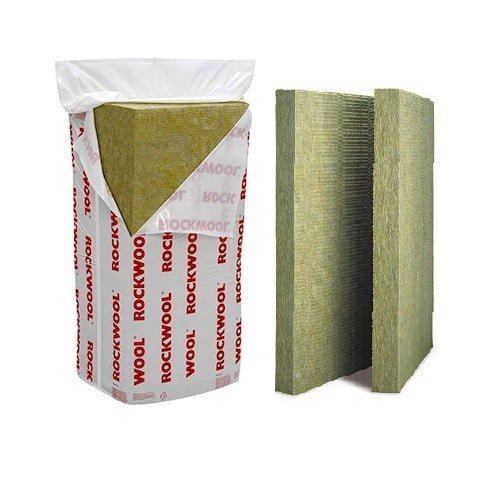

Rockwool is a manufacturer of mineral wool and insulation materials that is used all over the world. They are a local organisation that offers a high-quality range of sustainable insulation products mainly used by the building and construction industry. Their products can be used for many different types of application within both residential and commercial buildings including roofs, lofts, and walls.

Their wide range of products included Rockwool Flexi Slab, Rockwool Cavity Wall, and semi rigid acoustic insulation and many more well-known products.

Why Use Rockwool?

They are known for their high quality and durable products that provide sound insulation properties and superior thermal and fire performance. Rockwool products when installed correctly are extremely durable and can last as long as the building itself. It is a well-known and well trusted establishment. Most products are lightweight which can make installation and transportation of the product easier. Some of the products are multipurpose which can create less waste and ease when ordering. Rockwool products are produced with sustainability in mind. When a residential or commercial building is installed with good quality insulation you instantly save money on energy bills.

ROCKWOOL PRODUCTS:

RW SLAB RANGE

The RW slab range consists of RWA45, RW3, RW5 and RW6 and often used for its high-performance acoustic properties. This range aims to offer solutions for multiple applications such as roof, floor, wall, and loft insulation and provide excellent thermal, acoustic and fire insulation (Euroclass A1). The Rockwool sound insulation slab range is made up of high-quality resin bonded slabs in a variety of thicknesses and densities. Specialist facings are available to order to meet the specifications of unique projects. The RW sound insulation slab range is highly recommended it the construction and building industry.

ROCKWOOL CAVITY RANGE

Rockwool Cavity insulation is specifically designed for masonry walls. It can be used for both new buildings, renovations, and extensions in both residential and commercial buildings. The slabs prevent moisture and provide long term insulation. The slabs consist of a semi-rigid and full-fill insulation that is lightweight and easy to handle. The Cavity batts make installation simple and provide a close fit against the inner leaf and outer leaf. They have a thermal conductivity of 0.037W/mK. Other Rockwool cavity products include partial fill cavity slabs, Full fill cavity batts, Cavity Barriers, Insulated DPC, Energysaver, TCB Cavity Barrier and PCWB Cavity Barrier.

ROCKWOOL ROLL RANGE

The rockwool roll range products include rockwool roll, Twinroll, Rollbatt. These products are designed to ensure great quality acoustic and thermal Insulation. They are used for a wide range of building and construction applications including roofing and flooring needs.

Twinbatt rolls can be used fo suspended ceilings. In can also be used for other applications and provides excellent fire resistance. This product has a thermal conductivity is 0.044 W/mK.

Rockwool Rollbatt is used to reduce noise levels and provide acoustic insulation as well as increased thermal resistance. The product’s thermal conductivity is 0.044 W/mK.

Rockwool roll is best used for loft insulation and horizontal applications. It provides great quality acoustic and thermal performance as well as excellent fire resistance.

ROCKWOOL FLEXI

Rockwool Flexi is a mineral wool insulation with unique flexible edging along on side that is designed for multiple insulation purposes. The flexible edge is designed to ensure the perfect fit installed between insulation and supporting framework. This product is lightweight and easy to install. When installed correctly is can provide long term high-quality insulation. It is suitable for use all over the home, in pitched roof rafters, framed external walls, internal partitions, intermediate floors, separating walls and floors, and timber suspended ground floors.

RAINSCREEN DUO

Rainscreen Duo Slab is an insulation product that is suitable when it comes to protecting your residential or commercial property from the environment and all-weather conditions. When installed correctly it can provide thermal protection and improved acoustic performance as well as protection from weather. Rainscreen product is BRE tested and approved by BBA and is A1 Combustible.

Other Rockwool Products:

Rockwool has many other products available to suit your insulation needs such as cladding insulation, Flat roof insulation included acoustic fills and many more. Always consult your builders or contractors if you are unsure of what product you need for your project and follow the installation guide given when you receive your product.

Below are a list of additional Rockwool products available on our website:

A guide to the RW range

The Rockwool RW range is a top selling range of insulation slabs. The acoustic insulation material that is used in the RW range is made from stone wool. This is an excellent material for blocking, absorbing and even enhancing sound when required. The acoustic capabilities of the RW range means, the use of the products enhances the acoustic performance of the system in which the material is installed – both in new and existing buildings. In addition to having great thermal and acoustic qualities, stone wool also boasts excellent fire and water resistant qualities.

The RW range is durable, flexible and easy to install. RW insulation slabs can be fitted to walls, floors, and ceilings – or installed in roofs and facades.

Rockwool RW range insulation slabs are free from harmful gases (CFC and HCFC) and are easy on the environment. They do not add to the formation of any gases with Ozone Depletion Potential (ODP) or Global Warming Potential (GWP). It complies with the safety conditions for fire protection without any health hazards.

The Rockwool RW range includes RW3, RWA45, RW5, and RW6. See the individual product specifications below. Find the full range here – Rockwool RW Slab

The RW range is designed to create a safer, more comfortable environment that meets building regulations.

RW Range Protective Qualities

Stone wool improves the internal sound field quality by absorbing echo and reverberation within the room, contributing to good room acoustics. In addition to this, it can reduce sound transmission by blocking sound from the outside to the inside of the building, and from one room to another. This includes unwanted noise – airborne, impact, neighbouring walls, media transfers and rain noise. The resilience of stone wool means that is can isolate and dampen vibrations. In addition to this, Rockwool RW slabs are classed as non-combustible, which means they will help prevent the spread of flame. It has been proven that Rockwool can reduce the transfer of heat to another space for long periods of time (in some cases over 90 minutes) reducing damage levels. Furthermore, the melting point of stone wool is over 1000ºc. This allows more time for building occupants to evacuate in the event of a fire. The fire safety performance of the RW range lasts a lifetime with no maintenance required. Stone wool does not contain flame retardants.

Rockwool RW range boasts outstanding thermal qualities. This means installing Rockwool slabs can dramatically reduce heating, cooling, and ventilation costs and therefore reduce a building’s carbon footprint. In some cases, energy bills can be reduced up to 30% installed correctly. A major benefit to insulation slabs is that they are easy to install. Using Rockwool to control internal climates means warmer winters and cooler summers.

Rockwool RW Range Applications

The RW range is an all-round performer and manufactured for a range of general building projects and specialist applications. These multi-purpose slabs are designed for commercial,

leisure, industrial buildings including partition walls, ceilings, floors, and roof applications. See all applications methods listed below.

- Ceilings – Suspended ceiling

- Walls – Steel frame systems

- Walls – Timber frame systems

- Roofs – Pitched roofs between rafters and flat roofs

- Floors – ground floors, separating floors and intermediate floors

When installing any RW range product, we advise that you take on board these top tips.

- Prepare your surface – Build a stud wall or suspended ceiling first, to make sure there’s room for installing acoustic insulation boards or other products.

- Measure the space – Take measurements of the wall, floor or ceiling being insulated to get the right amount of material.

- Check for leakage – See if there are areas where sound escapes outside of the main wall, floor, or ceiling, and if a solution is required.

Which RW range product do I need?

The RW product range differs by density, thickness, and thermal conductivity. The RW product you choose will depend on the thickness of the slab you require. Once you have measured your required thickness you should take in consideration the level of sound proofing your project requires. The higher the density the better the acoustic quality, the best acoustic product in the range is the RW6 slab. Another thing to consider Is the thermal quality. The lower the density the better the thermal quality, the best thermal product in the range is RWA45.

Rockwool have developed technology in a way that allows waste from other industries to be used as alternative raw material. The building sector produces a third of all waste, much of which ends up in landfill today. Rockwool currently offers recycling services on building insulation in European markets where short distances support closed loop recycling as the most sustainable solution.

The RW range products can be easily removed when a building is renovated and recycled back into new products. Stone wool can be recycled indefinitely again and again, into new stone wool.

RWA45

Rockwool RWA45 is a robust insulation material made up of a high-quality mineral wool resin bonded slab which makes for a great insulator with high thermal quality. The high-quality materials are also extremely water repellent. RWA45 is 1200mm x 600mm and has thicknesses between 25mm and 120mm.

Fire performance can help to compartmentalise rooms, reducing fire spread and damage. The fire performance of the RWA45 and the RW range will give people more time to get out of the building and reduce the deterioration of the building caused by the spread of flames. The RW fire performance is non-combustible.

What does RWA45 mean?

RWA45 is slab insulation. This means that this is a preformed slab rather than a roll or a sheet. The slab measures 1200mm x 600mm which ensures speedy insulation. Rockwool RWA45 is named after Rockwool Acoustic as well as its density properties in that it has a density of 45Kg per cubic meter.

RW3

Rockwool RW3 is a robust insulation material made up of a high-quality mineral wool resin bonded slab which makes for a great insulator with high thermal quality. The high-quality materials are also extremely water repellent. RW3 is 1200mm x 600mm and has thicknesses between 25mm and 100mm.

Acoustic Quality – Rockwool RW3 and all other products within the range is an acoustic product and works in two distinct ways to reduce noise, either by impeding the transmission of sound through an element of the structure or by absorption of sound at the surface. The structure of the fibres in RW3 slabs make them ideal for use as a sound absorber.

The RW3 slabs offer specialist facings including black tissue, white tissue, and ALU are also available to order to achieve the specific building regulations. RW3 slabs have a density of 60kg/m3. The lesser the density the better thermal quality due to the slabs slowing the air flow travelling through the walls.

Rockwool RW3 vs RW5

RW3 has a density of 60kg/m3 and ranges between 25mm and 100mm, while RW5 has a density of 100kg/m3 and ranges between 25mm and 150mm. While the lower density is best when it comes to thermal quality, the high density of the RW5 will make the slabs a better sound absorber and will have better acoustic qualities.

What is the difference between Rockwool RWA45 and RW3?

RW3 has a density of 60kg/m3 and ranges between 25mm and 100mm, while RWA45 has a density of 45kg/m3 and ranges between 25mm and 150mm.

RW5

Rockwool RW5 is a robust insulation material made up of a high-quality mineral wool resin bonded slab which makes for a great insulator with high thermal quality. RW5 is 1200mm x 600mm and has thicknesses between 25mm and 150mm.

The thermal quality of the RW range will mean more controlled internal temperatures within residential and commercial environments. The range has thermal conductivities of 0.034W/mK and 0.035W/mK. This will result in less heat escaping the building and cheaper energy bills as a result. The Water repellence of the slabs will also prevent condensation, mould, and rot build up.

The RW range has a variety of densities throughout the products of 45kg/m3 (RWA45), 60kg/m3 (RW3), 80kg/m3 (RW4), 100kg/m3 (RW5), 140kg/m3 (RW6).

Is Rockwool sound insulation good for thermal?

Yes, Rockwool insulation has natural inherent properties for thermal, fire and sound which is present in all products in the RW range. Therefore, if you are using a sound insulation slab, you will automatically get a quality thermal and fire performance.

RW6

Rockwool RW6 is a robust insulation material made up of a high-quality mineral wool resin bonded slab which makes for a great insulator with high thermal quality. The high-quality materials are also extremely water repellent. RW6 is 1200mm x 600mm and has thicknesses between 50mm and 100mm.

ROCKWOOL RW Slabs are highly water repellent and non-hygroscopic. The water repellent qualities of the insulation prevent moisture build up, damp and rot. This can help to prevent damage occurring within the buildings structure that can be caused by moisture.

Below are a few frequently asked questions that we get about the RW range.

Is stone wool the same as rockwool?

ROCKWOOL is a company that manufactures stone wool insulation. Rock wool and stone wool is also known as mineral wool. Stone wool is created by spinning molten rock and minerals with steel slag to create a cotton-candy-like wool product.

Does rock wool contain asbestos?

Rock Wool manufactures products for residential, industrial, and commercial buildings including specialist projects such as marine applications, none of which contains asbestos.

Which is better Rockwool or glass wool?

While Glass wool products are more versatile & cost-effective at lower weights, Rockwool is 10% thicker to give the same performance. Rockwool is also completely water-resistant whereas Glass wool may allow water to penetrate at very low density.

Why do we need acoustic insulation?

Noise can affect health and wellbeing in many ways. This includes quickening hearing loss to disrupted sleep and reduced productivity levels. Sound insulation can protect those living and working in buildings against noise exposure. Acoustic insulation will provide you with comfort and privacy due to the reduction of sound transmission and vibration passing through building elements.

What is the difference between the products in the RW range?

All the products in the RW range are manufactured 1200mm by 600mm with the same Rock wool materials however the slabs differ by density, thermal conductivity, and available thicknesses.

What is density?

Density is the level of compactness of a material. Density is the measurement of how tightly a material is packed together. It is defined as the mass per unit volume. Density Symbol: D or ρ Density Formula: ρ = m/V, where ρ is the density, m is the mass of the object and V is the volume of the object.

Rockwool Sound Insulation

Rockwool is a popular choice for sound insulation because of its high density and ability to absorb sound waves. Rockwool is often used in walls, floors, and ceilings to reduce the transmission of sound between rooms or between different levels of a building.

One of the key benefits of using rockwool for sound insulation is its ability to absorb a wide range of frequencies. This means it can effectively reduce both low and high-frequency sounds, such as traffic noise or voices. Additionally, Rockwool sound slab have high density and are resilient. This makes Rockwool Sound Slabs effective at dampening sound vibrations, further reducing the transmission of sound.

Rockwool sound slabs are made from a fire-resistant insulation material, which makes it a great choice for use in buildings where fire safety is a concern. It is also non-toxic and does not release any harmful chemicals, making it a safe and environmentally friendly option.

You can buy different forms of Rockwool on our website. This includes batts, rolls, and loose-fill, making it easy to install in various types of spaces. Additionally, it can be cut and shaped to fit around electrical and plumbing fixtures, providing a snug fit.

Overall, Rockwool sound slabs are an effective and versatile sound insulation material that can help reduce noise transmission in buildings while also providing fire resistance and environmental benefits.