Cavity Wall Insulation

We supply cavity wall insulation from leading manufacturers such as Isover, Celotex and Rockwool insulation. At Trade Insulations, we take pride in providing top brands of cavity slabs and cavity insulation boards. We sell popular cavity wall insulation boards such as the Celotex Thermaclass and CW4000 range. The cavity insulation on our website is available to purchase in a variety of thicknesses and sizes.

Our cavity slab range boasts thermal, acoustic, fireproof, and water repellent properties. In addition to this, cavity slab insulation such as the Isover cavity range is rot proof, odourless, non-hygroscopic. This means they do not encourage vermin and also the growth of mould, fungi, or bacteria. Full specifications of the products can be found on the product pages.

Showing 1–16 of 95 results

Cavity Insulation

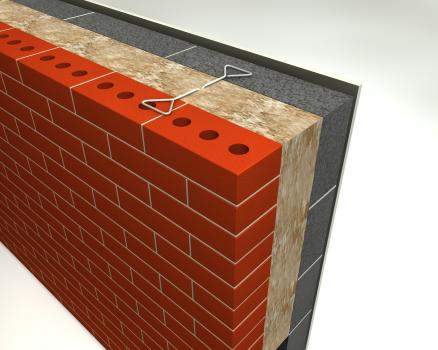

Cavity walls have a hollow centre. As a result, they are composed of two “skins” separated by a hollow chamber (cavity). Skins are usually masonry, such as bricks or cinder blocks. The masonry material absorbs rainwater and humidity, making it an extremely absorbent material.

Building cavity walls became prevalent in the United Kingdom during the 1920s. As early as the 4th century, stone ties were used to connect the two skins. During the 20th century, metal ties were used. Early cavity widths were narrow so that moisture could be reduced from getting into the interior of buildings. In the 1970s, cavity insulation became standard, and it became mandatory in the 1990s.

By insulating cavity walls, a house is also less likely to lose heat through its walls and therefore be kept warm more efficiently. Cavity wall insulation can also prevent convection as well as make a house warmer by preventing heat from escaping. About a third of the heat lost by an uninsulated home escapes through its walls.

Cavity wall insulation is a simple and cost-effective way to improve the energy efficiency of a building. By filling the empty space between the inner and outer walls of a building, it can help to reduce heat loss and lower heating costs.

We sell both cavity slabs and cavity wall boards. All of our lead times and prices are available on our product pages. In addition to this, you can also find product data sheets and specific technical information. The cavity insulation you need will be bespoke to the requirements of your project. If you are unsure on what you need, then we recommend that you speak with an architect who will be able to guide you on what you need.

What are the benefits of installing cavity wall insulation?

One of the primary benefits of cavity wall insulation is energy savings. During the winter, warm air inside your home can escape through the walls, causing your heating system to work harder to maintain a comfortable temperature. This can lead to higher energy bills. By insulating your walls, you can reduce the amount of heat that is lost, which can lead to significant savings on your energy bills.

Another benefit of cavity wall insulation is improved thermal efficiency. Insulating your walls can help to keep the warm air inside your home, making it more comfortable to live or work in. This can be especially beneficial in older homes or buildings that may not have been designed with energy efficiency in mind.

Cavity wall insulation can also help to reduce noise transmission through the walls. This can be especially beneficial if you live in a busy or noisy area, or if you have neighbours ors who are particularly loud. By reducing the amount of sound that can pass through the walls, cavity wall insulation can help to create a more peaceful and comfortable living or working environment. For more information on why you should use Cavity Wall Insulation, you should visit the Energy Saving Trust's article on Cavity Insulation.

In addition to these benefits, cavity wall insulation can also have a positive impact on the environment. By reducing energy consumption, insulation can help to lower greenhouse gas emissions and contribute to a more sustainable future.

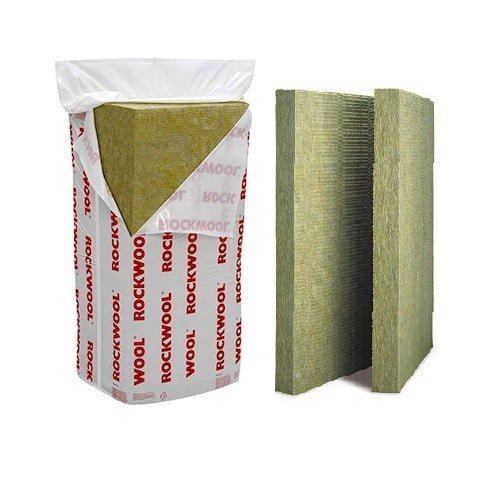

Cavity slabs

Cavity slabs are a type of insulation used to insulate cavity walls. Cavity slabs come in a variety of sizes, styles, and thicknesses. For example, Isover cavity slabs are manufactured with a water repellent additive. They are also rot-proof and therefore fit for purpose. Cavity slab insulation is popular as it is easy to install and provides excellent thermal performance.

Cavity slabs work by filling the air space of a cavity wall with material that inhibits heat transfer, cavity wall insulation is used to reduce heat loss through that wall. Cavity slabs are often made from glass mineral wool, which is the ideal material for insulation.

Cavity slabs can restrict moisture from passing through the walls. Water can pass through the outer wall because it is porous. Cavity slabs can trap the water and allow it to run down to the ground rather than through the inner wall. By using a water repellent cavity slab, you essentially remove the environment for mould to form. This gives cavity slabs more use than simply insulation.

Below is a breakdown of some of the popular cavity slabs that we sell.

Isover Cavity Slabs

Isover cavity slabs are a very popular cavity insulation product. They are lightweight and made from glass mineral wool. In addition to this, they are classed as non-combustible. The Isover cavity slab range features Isover cavity slab 32, Isover cavity slab 34 and Isover cavity slab 36. These slabs are available in a variety of thicknesses to suit your requirements.

Dritherm Cavity Slabs

Dritherm cavity slabs are manufactured by Knauf Insulation. They are made using Knauf's innovative ECOSE technology, We sell both Knauf Dritherm 37 and Dritherm 32 cavity slabs. These slabs are known for their excellent thermal performance. In addition to this, they boast both fire and water resistant properties. These are available in many thicknesses.

Rockwool RWA45

The Rockwool RWA45 range is made from stone wool, which is known for its excellent thermal properties. These slabs are technically classed as acoustic slabs due to their great soundproofing properties. They also boast a thermal conductivity of 0.035W/mK. The Rockwool RWA45 is available in thicknesses ranging from 25mm up to 120mm.

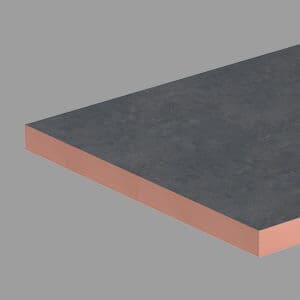

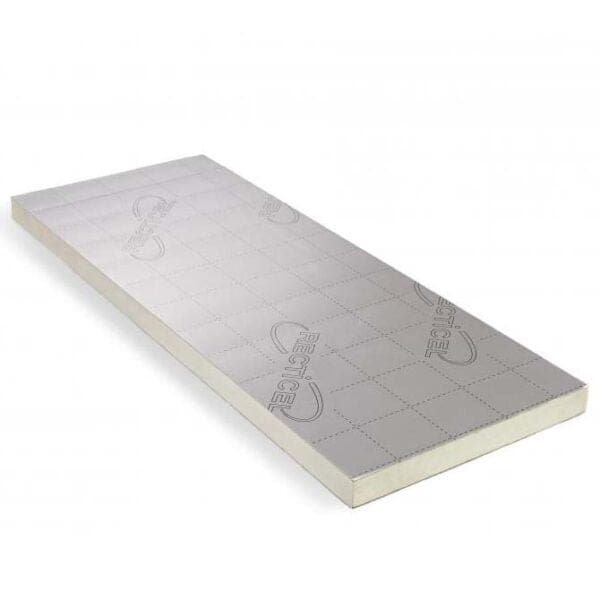

Cavity wall boards

The purpose of cavity wall boards is to help improve the thermal performance of a building. Overall, this can help to achieve a reduction in heat loss in colder periods and heat gain in warmer climates. Cavity wall boards are typically made from either polyisocyanurate (PIR) or phenolic foam. Both materials offer outstanding thermal properties.

Cavity wall boards such as the Celotex CW4000 range feature low emissivity foil facings to further enhance thermal resistance. This type of insulation is suited for use in both new builds and renovation. They can help achieve desired U-values with minimal thickness. Please note that every construction project is different therefore will have different requirements.

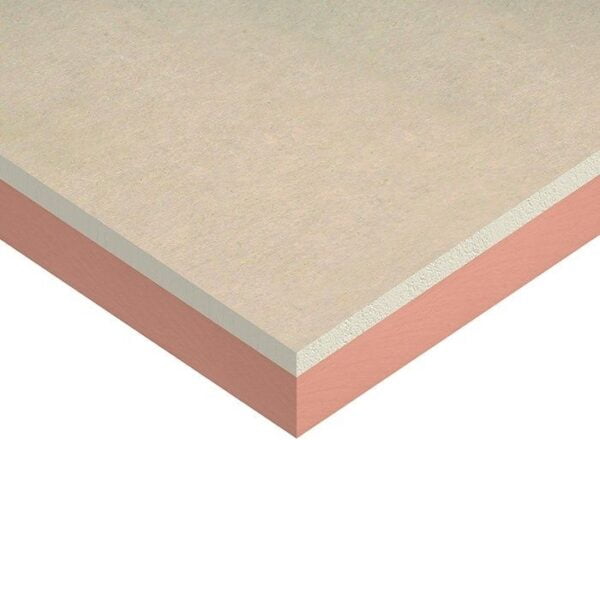

Celotex Thermaclass 21

The Celotex Thermaclass Cavity Wall Board 21 is made for full-fill masonry cavity wall applications. At its core, the board incorporates PIR (polyisocyanurate) and is complemented by a low emissivity foil facing to enhance thermal efficiency. Additionally, it employs tongue and groove edges. It comes in a variety of thicknesses, including options of 90mm, 115mm, and 140mm, catering to diverse construction needs.

Celotex CW4000

This is another very popular cavity wall board product by Celotex. It is made using high-performing polyisocyanurate (PIR) and suited to partial fill applications. It is notable for its exceptional thermal efficiency, which is enhanced by a low emissivity foil facing. It achieves a thermal conductivity of 0.022W/mK. The CW4000 range is available in sizes ranging from 50mm to 100mm,

Recticel Eurowall

Recticel Eurowall cavity wall board range features both 'Eurowall' and 'Eurowall Plus'. The difference between these two is that 'Eurowall' is designed for partial fill applications whereas 'Eurowall Plus' is designed for full fill. Both of these boards are made using PIR, which is an excellent insulation material.

Kingspan K106

Kingspan K106 features a unique phenolic core. The K106 Cavity Wall Insulation Board features a fibre-free, rigid phenolic core that is thermoset for durability. This board is uniquely designed with a low emissivity composite foil facing on one side, and the opposite side is complemented by a polypropylene fleece that is firmly bonded, enhancing its insulation properties.

What is the difference between cavity slabs and cavity boards?

The primary purpose of cavity insulation is to create a barrier that prevents heat from escaping through the walls. This process helps to maintain a comfortable temperature inside the house, regardless of the external weather conditions.

The insulation material used for cavity walls is typically PIR or mineral wool. These materials have excellent insulating properties and are capable of trapping air within their structure. The insulation act as a barrier, preventing the transfer of heat from the inside to the outside and vice versa.

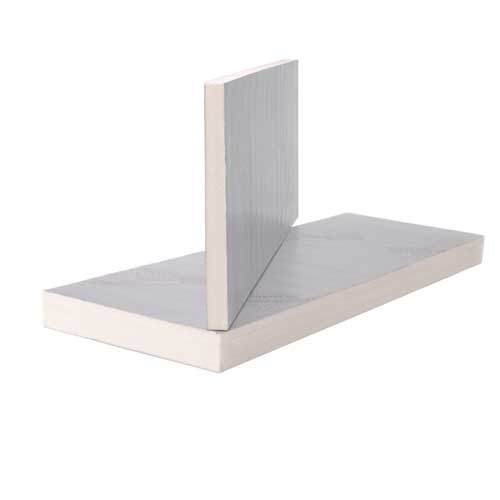

Cavity boards and cavity slabs are both types of insulation that are used to fill the empty space between the inner and outer walls of a building, known as a cavity. The main difference between the two is the material they are made of and the method of installation.

PIR cavity boards are made of rigid insulation material and are installed in the cavity by being cut to the appropriate size and shape, then inserted and secured in place. They are available in different thicknesses to suit different needs. Cavity boards are ideal for use in new builds and as part of a retrofit insulation project.

Cavity slabs, on the other hand, are made of a flexible insulation material and are installed by blowing the insulation material into the cavity using specialised equipment. The insulation material used in cavity slabs is typically made of cellulose, mineral wool, or polyurethane foam. Unlike cavity boards, cavity slabs do not need to be cut to size, making them a more flexible and versatile insulation option. Cavity slabs are ideal for use in existing properties as they can be installed without disturbing the internal decor.

The pros and cons of cavity boards and slabs

Both cavity boards and cavity slabs have their own advantages and disadvantages. Cavity boards offer a higher thermal resistance, and are less likely to settle or compress over time, which can affect their insulation properties. They are also ideal for use in properties where access to the cavity is limited. However, cavity boards can be more difficult to install when compared to slabs.

Cavity slabs, on the other hand, are easy to install and are a good option for properties where access to the cavity is limited. They are also less disruptive to install, as they can be installed without the need to disturb the internal decor of the property. However, cavity slabs are not as effective as cavity boards and may settle over time, which can affect their insulation properties.

In conclusion, both cavity boards and cavity slabs are effective options for insulating the cavities in a building, but the choice between them will depend on the specific needs of the property and the desired level of insulation. It is important to consult an architect to determine the most suitable option for your property.