When buying insulation, it is important that you know information regarding thickness tolerances. This ensures that you understand the product you are installing.

In this guide, we will touch upon thickness tolerances and explain the importance of understanding thickness tolerances.

What are thickness tolerances according to EN 823

Thickness tolerances are an essential aspect of ensuring quality and consistency in various industries. In the context of insulation materials, these tolerances are determined in accordance with the guidelines provided by the European standard EN 823. This standard defines the requirements for insulation products, specifically those with a declared class of T2.

EN 823 sets out the specifications for the thickness tolerances that manufacturers must adhere to. This means thicknesses are not strictly required to be exact but must be within a set range. Insulation tolerances provide a range within which the thickness of the material is allowed to deviate. By establishing these limits, the standard aims to maintain a level of uniformity and reliability in the performance of the insulation materials. By adhering to these tolerances, manufacturers can guarantee that the insulation material will perform as expected and provide the desired level of thermal and acoustic insulation.

What are insulation thickness tolerances

EN 823 allows for a range for the thickness of the material to deviate. This means that thickness does not strictly need to be identical as long as it falls within the set range. The amount the tolerance is allowed to deviate is based upon the nominal thickness of the insulation product. The range in accordance to EN 823 can be seen below

| Nominal thickness (mm) | Tolerance |

| < 50 | ± 2 |

| 50 to 75 | ± 3 |

| >75 | +5, – 3 |

The correct way to measure an insulation board

Before you begin, ensure you have an undamaged and high-quality tape measure or calliper or micrometer. Failure to do this may result in incorrect test results.

The thickness test, as outlined in EN823, requires placing the product or sample on a level surface. A flat pressure plate is then positioned on top and the gap between them needs to be measured.

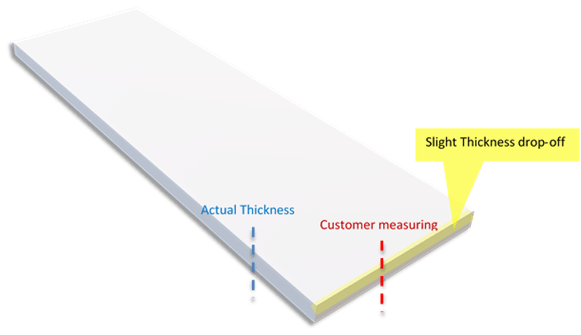

For example, if you consider a board measuring 2400x1200mm undergoing this test. If there is a minor reduction in thickness only within the final 15-20 mm of the 1200mm side, it would not affect the outcome of the test.

An illustration of this can be seen below:

What is EN 13165?

EN 13165 provides further information and guidance related to the overall performance and characteristics of the insulation product. This standard covers aspects such as thermal conductivity, water vapor permeability, and mechanical properties, in addition to the thickness tolerances defined in EN 823.

Overall, the combination of EN 823 and EN 13165 ensures that manufacturers produce insulation products that meet the necessary quality and performance standards. These standards play a vital role in the construction and other industries where insulation materials are utilised, as they contribute to the energy efficiency and comfort of buildings while promoting sustainable practices.