We boast a wide range of floor insulation products available to buy on our website. We stock top brands such as Celotex, Kingspan and Recticel. At Trade Insulations, we offer our very best price on floor insulation. Insulating a floor can help a property retain heat and therefore increase comfort and reduce heat loss. We sell insulation products, which are ideal for insulating concrete floors, suspended floors, and underfloors as well as simple flooring areas. From insulation boards to slabs, Trade Insulations is the best place to buy insulation for the floor.

Our floor insulation products are carefully selected to provide you with a variety of quality solutions. this allows you to keep your home warm in the winter and cool in the summer. Whether it is for a home or a large commercial space, our floor insulation options cater to all needs.

By preventing heat loss through the floor, you can significantly reduce your energy consumption. In addition to this it can help lower your heating bills, whilst reducing your carbon footprint.

We offer a wide range of floor insulation materials, each designed to meet specific requirements. From traditional fiberglass and mineral wool to more innovative options like PIR boards. We have everything you need to insulate your floors effectively.

Our products are not only excellent for new constructions but also perfect for retrofitting existing floors. So, whether you’re renovating your home or planning a new building project, our products are versatile enough to fit any scenario.

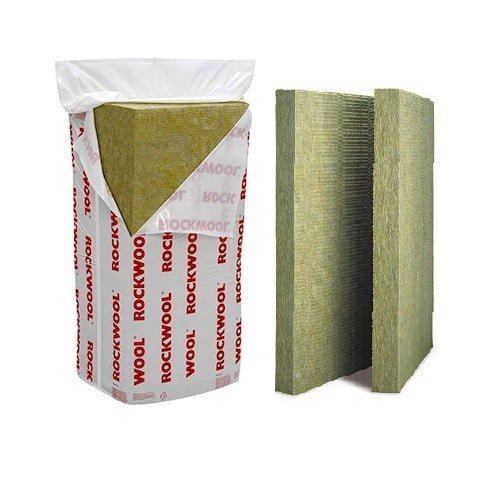

In addition to their insulating properties, some floor insulation products may feature soundproofing capabilities. These products help to dampen noise and improve the overall acoustics within your space. This helps to further reduce noisy footsteps and echoing rooms. The Rockwool Flexi slab range is great for providing both thermal and acoustic in flooring applications.

All of the product pages below feature helpful information as well as attributes and data sheets. This means you can be confident that you are buying the right product. If you need additional advice or need help using our website, then feel free to use our live chat or contact us for any queries. If you are looking for something you can’t see then let us know because we will most likely have a better alternative available.

Showing 1–16 of 183 results

Celotex 100mm PIR Insulation Board – GA4100 (2400mm x 1200mm x 100mm) 2.88m2

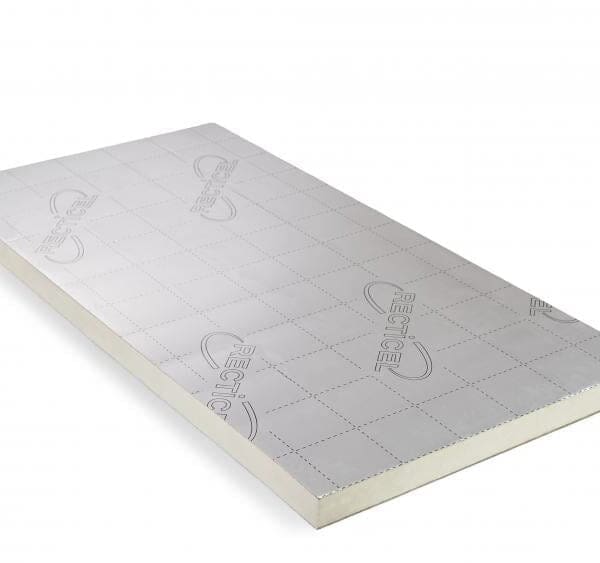

Original price was: £39.99.£29.25Current price is: £29.25.100mm Recticel GP Insulation Boards (1200x2400mm) – 2.88m2

Original price was: £39.99.£29.25Current price is: £29.25.Celotex 37.5mm Insulated Plasterboard (2400mm x 1200mm x 37.5mm) – PL4025

Original price was: £40.50.£31.90Current price is: £31.90.Rockwool 100mm RWA45 Acoustic Insulation Slab (1200 x 600mm) – 2.88m2 pack

Original price was: £28.50.£22.80Current price is: £22.80.ROCKWOOL Flexi – 1200 x 400 x 100mm – 86.4m2 pallet

Original price was: £999.07.£832.56Current price is: £832.56.ROCKWOOL Flexi Slab – 1200 x 600 x 100mm – 4.32m2 pack

Original price was: £47.39.£39.49Current price is: £39.49.100mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 8.64m2 pack

Original price was: £155.29.£129.56Current price is: £129.56.120mm Celotex Insulation Board – XR4120 (2400mm x 1200mm x 120mm) 2.88m2

Original price was: £51.99.£35.85Current price is: £35.85.25mm Recticel GP Insulation Boards (1200x2400mm) – 2.88m2

Original price was: £18.29.£11.15Current price is: £11.15.50mm Celotex Insulation Board – GA4050 (2400mm x 1200mm x 50mm) 2.88m2

Original price was: £25.15.£17.25Current price is: £17.25.50mm Recticel GP Insulation Boards (1200x2400mm) – 2.88m2

Original price was: £25.15.£17.25Current price is: £17.25.70mm Recticel GP Insulation Boards (1200x2400mm) – 2.88m2

Original price was: £34.89.£23.13Current price is: £23.13.75mm Celotex Insulation Board – GA4075 (2400mm X 1200mm X 75mm) 2.88m2

Original price was: £34.99.£23.86Current price is: £23.86.75mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 11.25m2 pack

Original price was: £179.22.£143.42Current price is: £143.42.Celotex 52.5mm Insulated Plasterboard (2400mm x 1200mm x 52.5mm) – PL4040

Original price was: £48.90.£39.91Current price is: £39.91.Insulation For The Floor

Insulation for the floor is simply insulation, which is placed beneath the floorboards. There are many different floor insulation products available on the market. The purpose of installing insulation for the floor is that it can help prevent heat from escaping through the floor. It is said that up to 1/5th of the heat in a building escapes through the floor. This is why it is important to ensure that a building has good insulation for the floor. In addition to this, the gaps between the floor as well as the skirting board may also require insulation. This is to help reduce potential cold drafts.

What are the benefits of floor insulation boards?

- Floor insulation boards improve the thermal quality of the property. This means a more temperature-controlled environment with cooler summers and warmer winters. Thermal quality means fewer drafts, less heat escaping the property and a more comfortable living and working space.

- Preventing heat and energy escaping through the roof you will save money on your energy bills as less energy will be needed to heat your property.

- With less heat escaping, it will have a positive effect on the global warming and climate change, making your property more energy-efficient and sustainable.

- When installed correctly, roof insulation will have a lifespan for as long as the building itself.

- Floor insulation materials are usually lightweight and easy to cut, handle, and install.

- Floor Insulation Boards hold a high compression strength making them the ideal product to hold weight such as furniture and being walked on etc..

- Floor insulation will have a lifespan matching the building when installed correctly.

Installing floor insulation boards

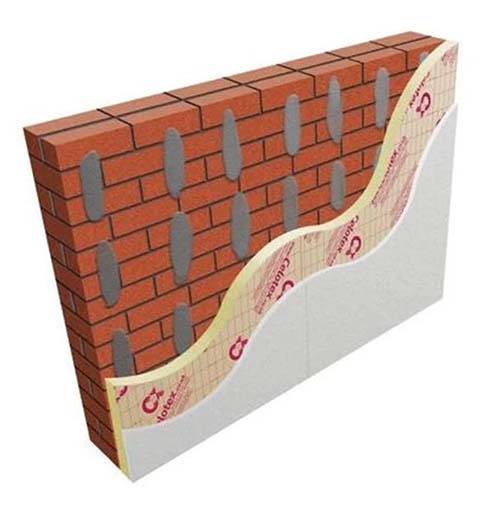

Solid floors can be insulated by laying the insulation on top. A damp-proof membrane is recommended to be placed in between the solid floor and insulation board to prevent moisture. Other materials can then be layered on top of the insulation to help with noise such as an acoustic barrier matt followed by underlay.

Concrete floors can be insulated by infilling sand over the surface and then laying a damp proof membrane on top of the sand, then lay the insulation boards and then the concrete. Then apply the underlay and chosen flooring.

Floor insulation boards can be cut by measuring the boards and marking a size guide. A fine-toothed saw can then be used, or the boards can be scored with a sharp knife, snapped over a hard edge, and scored on the other side.

Ensure a building professional is consulted before installing floor insulation. This is to ensure the insulation materials being used are the correct product for the building, this will avoid damage being caused. Always ensure the product meets the relevant national building regulations

If there is existing dampness or rot within the floor this should be cleared by a building professional before the insulation is installed. Insulating damp or rotten areas can cause further damage.

Floor Insulation boards are high-quality boards made up of a rigid polyisocyanurate (PIR) or phenolic core that has a layer of low emissivity foil or glass tissue bonded to each side. It is lightweight and easy to cut, handle, and install yet holds a high compression strength. The boards come in a variety and thicknesses and offer thermal conductivities ranging between 0.018W/mK and 0.022W/mK. Floor Insulation Boards are available from brands Recticel, Kingspan, Mannok, and more.

Reasons to insulate your floor

Installing insulation for floors can improve the energy efficiency of a building. This can help save on energy costs whilst raising the performance of a building. The ideal time to install floor insulation is when a new floor is being installed, however, floors can also be later retrofitted with insulation. Some people choose to upgrade their flooring with insulation in an effort to upgrade the environmental performance of a building. In addition to this, solid floor insulation can provide protection for piping systems. This means that a well insulated floor in the winter is at lower risk or a pipe bursting.

The install of floor insulation can reduce your carbon footprint. Furthermore, it means that less energy is needed to keep a house or building warm. The need for less energy means that energy bills are reduced, which therefore equates to year on year savings.

- Floor insulation can reduce heat loss

- It can reduce a households carbon footprint

- Solid floor insulation can provide protection for piping systems

- Floor insulation can lower energy costs

- Installng insulation for the floor can improve a buidlings performance

Another big motivation for people wanting to install floor insulation is that effective floor insulation can reduce drafts in a building. This is achieved by eliminating gaps between the floor and the ground where air can penetrate.

Different type of floor insulation

There are many different types of floor insulation. On our website we sell a range of top brands from the likes of Celotex and Kingspan. Floor insulation boards are popular insulation products for floors. There are many options when it comes to floor insulation boards.

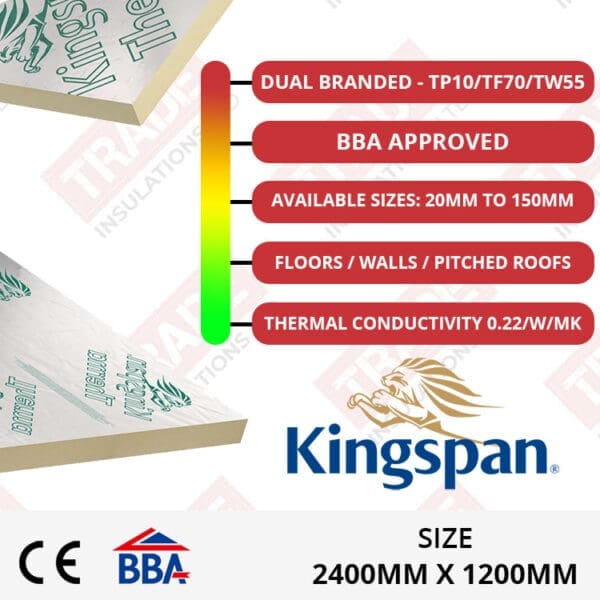

Kingspan Floor Insulation

Kingspan offer a range of floor insulation products. These are in high demand on our website. Kingspan K103 Floor Insulation Boards form part of the Kooltherm range and are a premium floor insulation board. These high performance boards are suitable for use on both solid concrete floors and suspended floors. In addition to this, Kingspan also have a PIR board designed for floors, which is called Thermafloor TF70. Another product by Kingspan is GreenGuard Floor Insulation Board. This has been specifcally designed to be used as a insulation board for floors. The benefit of using GreenGuard is that it boasts high compressive strength as well as having great insulative properties. Lastly, Kingspan have introduced an Optim R Flooring System, which is priced on application.

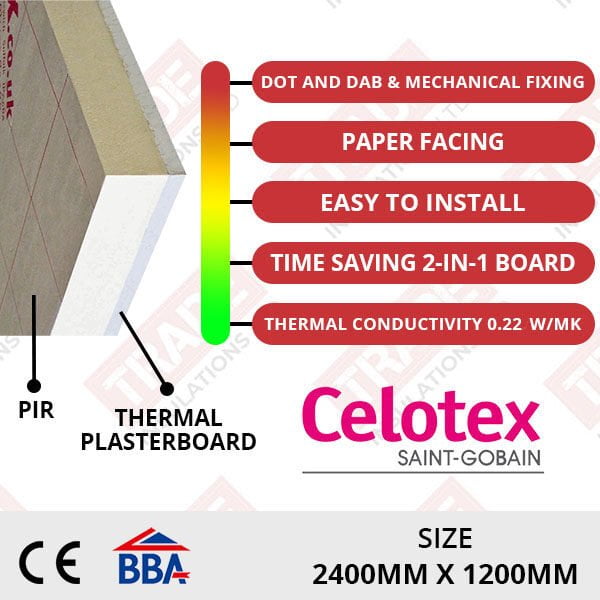

Celotex Floor Insulation

Celotex General Purpose PIR Boards are one of our most popular products. Being a general purpose PIR board, it means that it is suitable for many different applications. Floor insulation being one of them. Celotex PIR boards vary in thicknesses and are a cost effective solution for floor insulation. The brand Celotex are widely known and respected within the insulation industry.

Rockwool Floor Insulation

Rockwool are mainly a manufacturer of insulation rolls, slabs and batts. The Rockwool RW range features many different products, which are suitable for use as insulation for floors. A popular product in the RW range are the RWA45 acoustic insulation slabs. These slabs boast excellent thermal qualities as well as having acoustic properties. In addition to the RWA45, Rockwool Flexi slabs can be used in floors. These slabs are easy to install and are available in a variety of thicknesses and size dimensions. Area coverage information can be easily found on every product on our website so you always are well informed before making your purchase.

These are just a handful of the popular flooring insulation products on our website. If you have any additional questions, then feel free to get in contact with us. Our UK office is open on weekdays 8am-5pm. All email enquries are aimed to be answerered on the same working day.

Cheap Floor Insulation

At Trade Insulations, we believe in providing top brands at trade prices. The best part is, you don't need to be in the trade to get trade price floor insulation. As dedicated sellers of floor insulation, we sell insulation online in high volumes. This means we can pass our savings directly on to our customers. None of our floor insulation is second-hand, so rest assured that every product on Trade Insulations is brand new and fit for purpose. The prices you see on our website are rock bottom prices. We believe that everybody should have access to affordable floor insulation. If you are looking to buy cheap floor insulation, then we can help.

Floor insulation thickness regulations UK

The UK building regulations for floor insulation differs depending on the type of floor as well as the size, shape and construction. For rigid foam insulation, it needs to be about 90mm in thickness and for mineral wool, the thickness needs to be at least 150mm. A U value of 0.25 needs to be achieved. Additional factors in the actual construction of the building may affect U Value. To be certain, the best thing to do is contact a builder or architect to review your specific requirements. Most builders tend to install rigid foam insulation boards between the floor joists as these can be fitted tightly to eliminate gaps.

For more information view the governments The Approved Documents, which provide guidance on ways to meet the building regulations.

On this page, you will find every potential floor insulation products that you would need for a building project. Our easy to use website means that you can purchase insulation for floors in just minutes. If you are unsure of anything, we advise you to get in contact with us and we can answer any questions you may have. We offer a large range of floor insulation products. Whether it is concrete floor insulation or underfloor insulation – we have you covered.

How is underfloor insulation installed?

There are multiple application methods that can be applied when insulating your floor depending on the type of insulation you need, size, and where abouts in the floor structure in which it will be fitted. Floor insulation can be applied in suspended floors, solid floors, and concrete floors.

Insulation for suspended floors

Underfloor insulation can be applied in suspended floors by going underneath the floors into a basement space and fitting insulation into the joists and securing using netting material.

A suspended floor is when there is a space beneath the floorboards and that the floorboards are laying over joists.

If there is no basement the floorboards should be lifted, and insulation fitted into the joists. It can also be applied by fitting netting in between the joists first and then placing the insulation on top of the nets.

Insulation for solid floors

Solid floors can be insulated by laying the insulation on top of existing flooring and then covering the insulation with the chosen floor finish. A damp-proof membrane is advised to be laid in between the solid floor and insulation boards to avoid moisture.

This method is not always recommended as it can affect the rest of the properties fixtures and fittings such as raising skirting boards, raising electrical sockets, shaving the bottom of doors and that’s before clearing out the whole space and pulling up the floorboards.

There are several insulation manufacturers that provide underfloor insulation such as Kingspan, Celotex, Iko Enertherm, among others.

Underfloor PIR boards

Underfloor PIR insulation boards are manufactured from rigid polyisocyanurate (PIR), a lightweight foam board sandwiched between two foil facings. It is a lightweight product to ensure easy cutting, handling, and application. It provides a multi-purpose use including, walls, roofs, and floors. It is a much-liked product when insulating floors.

Using Insulation slabs as underfloor insulation

Slabs are a flexible material that provides multi-purpose use. They are easy to cut, install and handle making them easily fit within joists and timber frames. This is a common choice when insulating concrete floors. Insulation slabs are available from brands including Kingspan, Knauf, and Rockwool.

Remember, all of our product pages feature data sheets and in depth information so that you can be sure that you can find the right insulation product for your floor.