Trade Insulations is the go to place all your wall insulation needs in the UK. Whether you’re a homeowner looking to improve energy efficiency or a contractor seeking top-quality insulation materials, we have you covered. With a wide range of cutting-edge products from leading manufacturers, we are committed to providing sustainable and cost-effective solutions to keep your property warm, cosy, and eco-friendly. Explore our user-friendly website, find the perfect insulation materials tailored to your requirements, and embark on a journey towards a more energy-efficient future. Trust Trade Insulations for excellence in service and insulation expertise.

Below you can filter between the different types of insulation for walls categories as well as products. The product pages feature full descriptions as well as technical information and data sheets so that you can be well informed when purchasing insulation from us. We offer express delivery on a wide range of our products. Get insulation delivered straight to your home or site – it could not be easier.

Showing 1–16 of 309 results

Celotex 100mm PIR Insulation Board – GA4100 (2400mm x 1200mm x 100mm) 2.88m2

Original price was: £39.99.£29.25Current price is: £29.25.100mm Isover Spacesaver Loft Insulation – 14.13m2 Isover Loft Roll

Original price was: £32.69.£30.62Current price is: £30.62.100mm Knauf Acoustic Roll – (2x 600mm) – 12.36m2 roll

Original price was: £59.99.£55.40Current price is: £55.40.100mm Recticel GP Insulation Boards (1200x2400mm) – 2.88m2

Original price was: £39.99.£29.25Current price is: £29.25.12.5mm Plasterboard – Knauf Wallboard (12.5mm x 2400mm x 1200mm) (2.88m2) Tapered Edge

Original price was: £10.70.£9.35Current price is: £9.35.Celotex 37.5mm Insulated Plasterboard (2400mm x 1200mm x 37.5mm) – PL4025

Original price was: £40.50.£31.90Current price is: £31.90.Celotex CW4100 100mm Cavity Wall Board (1200mm x 450mm) – 3.24m2 pack

Original price was: £51.23.£45.00Current price is: £45.00.Kingspan Kooltherm K118 37.5mm Insulated Plasterboard (2400 x 1200mm) – 2.88m2

Original price was: £78.59.£65.49Current price is: £65.49.Knauf 25mm Acoustic Roll (2x600mm) – 26.64m2 roll

Original price was: £49.50.£42.99Current price is: £42.99.Knauf Dritherm 32 100mm Ultimate Cavity Slab (1200mm x 455mm) – 3.27m2 pack

Original price was: £36.42.£34.17Current price is: £34.17.Rockwool 100mm RWA45 Acoustic Insulation Slab (1200 x 600mm) – 2.88m2 pack

Original price was: £28.50.£22.80Current price is: £22.80.ROCKWOOL Flexi – 1200 x 400 x 100mm – 86.4m2 pallet

Original price was: £999.07.£832.56Current price is: £832.56.ROCKWOOL Flexi Slab – 1200 x 600 x 100mm – 4.32m2 pack

Original price was: £47.39.£39.49Current price is: £39.49.100mm Isover Acoustic Partition Roll – 11m2 Acoustic Insulation Roll

Original price was: £59.55.£53.99Current price is: £53.99.120mm Celotex Insulation Board – XR4120 (2400mm x 1200mm x 120mm) 2.88m2

Original price was: £51.99.£35.85Current price is: £35.85.Insulation for walls

Insulation for walls can be used to improve the thermal performance of a building. The purpose of wall insulation is to reduce heat transfer, making the interior spaces more energy-efficient and comfortable.

There are various types of wall insulation materials available on our website. This includes PIR boards and fiberglass. These materials work by trapping air pockets, which act as insulating layers and prevent heat from escaping or entering the building.

Insulation for walls is an essential component of energy-efficient construction and renovations, helping to maintain stable temperatures and improve the overall energy performance of buildings.

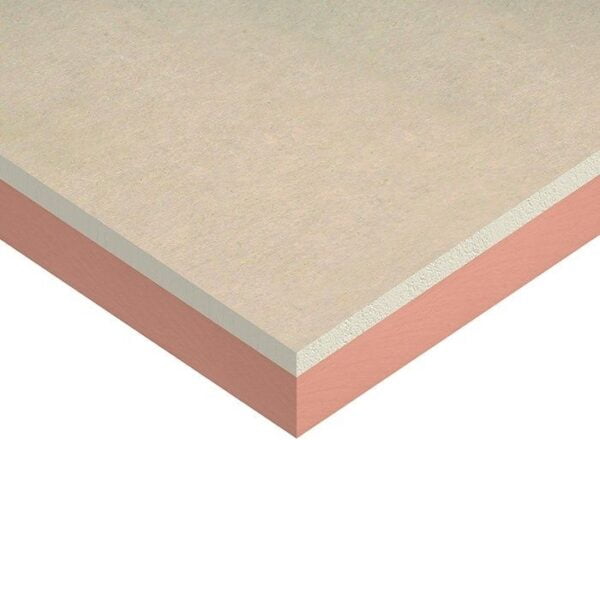

Rigid foam boards, also known as PIR insulation, are manufactured from polyisocyanurate. These boards provide high thermal resistance and can often be used for multiple purposes. For example, the Celotex PIR range can be used in walls as well as floors and roofs.

Other common wall insulation materials include fiberglass or mineral wool. Fiberglass is a lightweight and cost-effective option, which consists of fine glass fibers. These fibers create an effective thermal barrier. It is easy to install and can fit snugly between wall studs or in wall cavities. Mineral wool is slightly different as it is made from natural or synthetic fibers, which are derived from minerals. Rockwool is a known manufacturer of mineral wool insulation. Both fiberglass and mineral wall offer great fire resistance and sound absorption properties, making them ideal for both thermal and acoustic insulation. Additionally, it is said that mineral wool is resistant to mould and pests, ensuring a healthier indoor environment.

Insulated walls can contribute to a quieter and more peaceful indoor environment by blocking external noise pollution and having thermal qualities.

If you are looking to insulate a wall, we have every product you would need to achieve this.

Wall Insulation Boards

We stock a wide variety of wall insulation boards on our website. This includes top brands such as Celotex, Kingspan and Recticel. Our Celotex general-purpose boards are a very popular product when it comes to insulation panels for walls.

On our website, you can find thermal wall insulation boards for many types of wall applications. This includes cavity walls as well as solid walls.

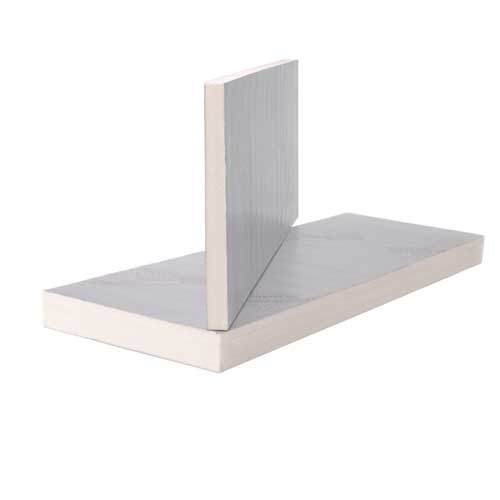

Wall insulation panels are a crucial component in creating energy-efficient and comfortable living spaces, offering both warmth in the winter and coolness in the summer. Among the various types of insulation materials available, PIR (Polyisocyanurate) insulation boards stand out for their exceptional thermal performance, durability, and versatility. Celotex, a leading brand in the insulation industry, is renowned for its high-quality PIR insulation boards, making it a popular choice among homeowners, builders, and architects.

PIR wall insulation boards are made from polyisocyanurate, a type of plastic closely related to polyurethane but with enhanced thermal performance and fire resistance. These boards are recognised for their excellent insulation properties, which stem from their fine, closed-cell structure that traps air and reduces heat transfer. PIR boards are lightweight and easy to cut and install, making them well-suited to wall applications.

On our website, we offer the very best price for wall insulation boards.

How to Insulate a Wall with PIR Boards

Insulating walls with PIR insulation boards is a good decision that can lead to substantial energy savings and a more comfortable indoor environment. An architect or building professional should be able to offer advice on which product/s you need. A professional can help you determine the thickness required for your boards.

Once you have purchased your inner wall insulation from us, you will need to gather additional equipment and PPE. This includes gloves, goggles, wall ties, measuring tape, a utility knife and mechanical fasteners.

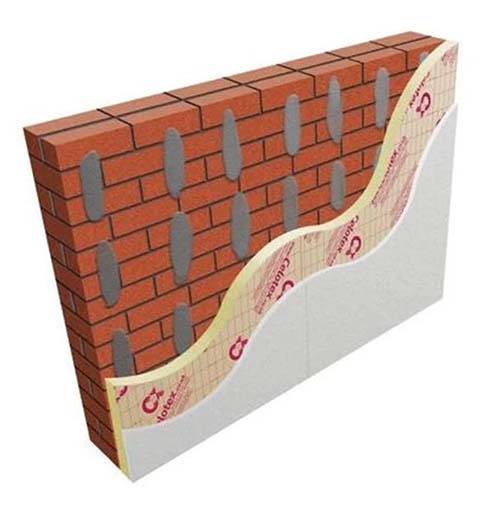

The type of installation will depend on the application, so we recommend reading the manufacturer's guide. Installing PIR cavity wall insulation, you would do the following:

- Position wall ties one course below the damp proof course, 600mm apart horizontally.

- Install subsequent rows of ties at 450mm intervals vertically and 900mm horizontally if possible.

- Secure the insulation boards between the ties using retaining clips.

- Ensure full and cut boards are held by at least three ties around their perimeters.

- Use insulated cavity closers for windows, doors, or openings.

- For cavities below the DPC level, use mechanical fixings to secure the boards.

If you were to upgrade solid walls with insulated plasterboard, then you could use the dot-and-dab method below:

- Apply adhesive at skirting, ceiling level, and openings for a continuous seal. Alternatively, use thin timber battens at perimeter edges.

- Align the insulation against adhesive and secure it in place. Add more adhesive if needed, following the manufacturer's instructions.

- After the adhesive sets, apply secondary fixings to the insulated plasterboard as per manufacturer recommendations.

- Ensure tight alignment of board joints and use appropriate tape and joint material to create a vapour control layer.

Wall Insulation Slabs

Insulation slabs are often used in cavities to improve both thermal and acoustic performance. Cavity wall insulation slabs are designed to fill the air gaps or cavities between the inner and outer walls of a building. These slabs are usually made of materials like mineral wool or fiberglass. They create a thermal barrier to improve performance. These insulation slabs can be easily slotted into the relevant cavity space. See the video below, which compares the installation of PIR boards vs Knauf Dritherm Slabs:

The benefits of insulating walls

Insulating walls offers numerous benefits, which we have outlined below:

- Insulating walls create a thermal barrier that can improve the thermal performance of the building.

- Wall insulation can help people to save money on their energy expenses. Over time, the cost savings can offset the initial investment in insulation.

- Properly insulated walls contribute to a more comfortable indoor environment. Insulation minimises drafts, cold spots, and temperature fluctuations, creating a consistent and pleasant living space.

- Using insulation with acoustic properties can help reduce noise pollution and reduce sound travelling through walls.

- Insulation reduces the need for excessive energy consumption to heat a home. This means fewer greenhouse gas emissions, therefore helps to build a more sustainable future.

- Wall insulation can reduce condensation and moisture build-up, causing damage to the building.

- Well-insulated buildings tend to fetch a higher price on the property market.

- Building regulations in England mandate the use of insulation in new constructions or renovations. The use of wall insulation can help with compliance.

- Better temperature control can reduce the risk of temperature-related health issues.

Please note that wall insulation properties will differ depending on the product. Ensure that you read the relevant data sheets.

Cheap Wall Insulation

If you need cost-effective wall insulation solutions, then you can order from us in no time at all. We take pride in offering a wide range of cheap wall insulation products online. With our competitive prices, you can achieve exceptional energy efficiency without it costing a fortune. We stock hundreds of products online and always offer our very best price.

It has never been easier to place an order and get your wall insulation delivered directly on-site. In addition to this, our prices are considerably less than many well-known builders merchants.

We offer various types of cheap wall insulation, including mineral wool, and rigid board insulation, suitable for different wall applications and insulation requirements. From cavity wall to stud wall insulation, we have everything you need.

Wall insulation is easy to install and can make a massive difference to the thermal performance of a building. At Trade Insulations, we only sell wall insulation products from best-selling trusted brands such as Knauf or Celotex.

Whether you're insulating a new construction or upgrading an existing property, Trade Insulations has the right solution for you. Browse this page for cheap wall insulation products and find the perfect fit for your insulation needs.

If you have any questions or need help using our website, please feel free to get in touch with the team. Our friendly team will be happy to assist you.