Discover our wide range of plasterboards as well as plaster and adhesives. Plasterboard is commonly used to create interior walls and ceilings. At Trade Insulations, we offer our very best price on all plasterboard and drywall products. We stock top brands such as Knauf, Siniat and British Gypsum. On our website, you can easily filter between the type of plasterboard you need. We plasterboard range includes wallboard standard plasterboard but also have specialist boards such as acoustic plasterboard or moisture resistant plasterboard. In addition to this, you will find all of the most popular plasterboard products on our website. This includes insulated plasterboards such as the Celotex PL4000, or our highly popular Knauf Wallboard Plasterboards. Order your plasterboard online today with us.

When it comes to installing plasterboard, it is very easy to handle and install. Many builders use plasterboard to create partitions to therefore create more organised use of the space. On our website, we offer our rock bottom prices on all drywall products. All of our product pages feature detailed descriptions as well as manufacturer data sheets. When you order with us, you can shop with confidence knowing that you can get your order delivered directly to your home or project on a date that suits you.

Benefits of Drywall

Standard plasterboard is typically made from gypsum, which is sandwiched between paper layers. In addition to standard plasterboard, there are also specialist plasterboards such as acoustic panels, which are designed to reduce noise pollution. There are many reasons as to why plasterboard is so commonly used in building projects. It is versatile as well as low cost, especially when purchased through our website. In addition to this, plasterboard boasts a lot of key benefits. One major benefit is that is easy to install when compared to other construction methods such as brickwork. It is a cost effective way of creating partitions whilst saving time. Plasterboard can also be painted or wallpapered. This means you can save both time and money on your project, whilst retaining a great finished result.

When it comes to sustainability, drywall has come a long way. Manufacturers such as Knauf use a process called Flue Gas Desulphurisation, which removes the byproduct sulfur dioxide and therefore reduces emissions. They also use 100% recycled paper liners, which are provided by a FSC certified paper factory. Plasterboards can also be recycled back into their raw materials, which makes them a great choice for the environment.

When purchasing plasterboard, ensure that you know the area of installation as well as your specific requirements. We advise that you order more plasterboard than you need to account for potential wastage. The application area may affect what drywall you need. For example, for humid environments such as bathrooms, you may need moisture resistant plasterboard. Please note, if you require specialist boards then you can see the breakdown of specialist boards below. If you are unsure of what you need, then we advise speaking with a building professional or architect.

Showing 1–16 of 38 results

What is Plasterboard?

Plasterboard is one of the most commonly used building materials in the construction industry. It is primarily used for partitioning, lining walls, and constructing ceilings in any type of building. This includes schools, hospitals, shops, and residences. In addition to this, specialist plasterboards can help to control condensation or provide fire protection, insulation or acoustic properties. Plasterboards are made from calcium sulfate dihydrate (gypsum), which is usually pressed between a facer and a backer.

The rise of plasterboard began during the end of the 1910s and throughout the 1920s. Today they are also known as wall boards, wall panels, gypsum boards. Plasterboard can be purchased in a variety of thicknesses and sizes to suit your requirements, however one of the most common size variants is 2.4m by 1.2m and 12.5mm in thickness. Another name plasterboard is 'drywall'.

When it comes to installing drywall, one of the most popular methods is known as the dot and dab method. You can read our full guide on how to dot and dab plasterboard You can also find all plaster and adhesives on our website as well as drywall tape (scrim tape).

Below is a breakdown of the different types of plasterboard that we sell.

Types of plasterboard

There are a variety of types of plasterboard that you can purchase from our website. The different types of plasterboard range from standard wallboard to specialist plasterboard, such as moisture or fire rated panels. Below is a full breakdown of the different types of plasterboard as well as what their intended use is.

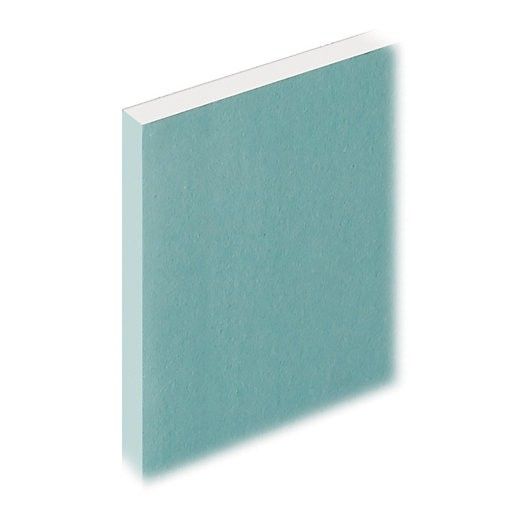

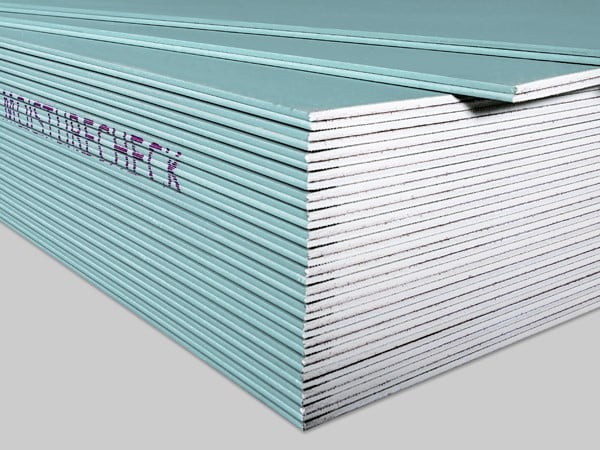

Moisture Resistant Plasterboard

Moisture resistant plasterboard, otherwise known as moisture panels, are a specialist plasterboard. Moisture panels are commonly made from gypsum and feature a wax or silicon additive. This additive helps to give these boards moisture resistant properties. This enables them to be used in areas of high moisture or humidity. Moisture resistant plasterboard is mainly installed in bathrooms or kitchens. The use of these boards helps protect from moisture related damage. Moisture boards are easy to identify due to their green colour.

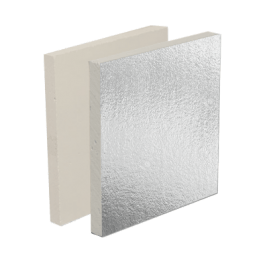

Insulated Plasterboard

Insulated plasterboards are a 2 in 1 product, which combines insulation with plasterboard. This means that they have all the aesthetic benefits of plasterboard as well as the thermal properties of insulation. Insulated plasterboard is often referred to as thermal plasterboard. They are easy to install and are designed to prevent heat from escaping. In addition to this, they are quick to install compared to traditional methods. This is because you only need to install the thermal plasterboard rather than installing insulation and plasterboard separately. This can cut down labour costs as well as help improve the thermal efficiency of a property.

Acoustic Plasterboard

Acoustic plasterboard is often called sound proof plasterboard. It is a specialist type of drywall that can help reduce the transmission of noise. This is possible due to the higher density of the sound panel. The higher density means that more sound is absorbed compared to standard wall boards. Acoustic panels are great for creating a more comfortable environment by reducing noise vibration and sound transmission. These sound panels are identifiable due to their blue colour.

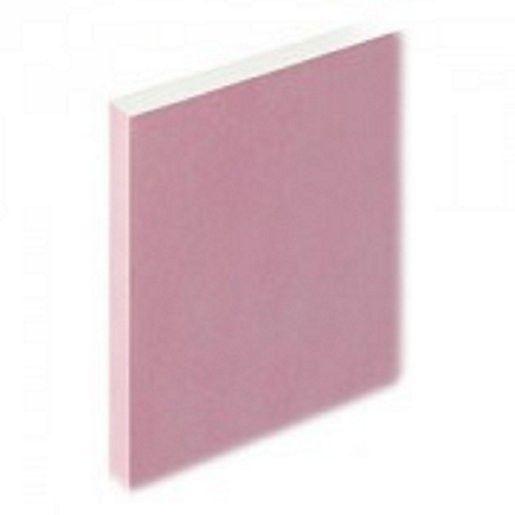

Fire Rated Plasterboard

Fire rated plasterboards are often referred to as fire resistant plasterboards, or even fire retardant boards. They are advised to be used in potentially high fire hazard areas. These specialist fire boards are designed to provide more fire resistance than standard wallboard. This means they have a higher burn time than standard wallboard. In the event of a fire emergency, fire boards can add crucial time to allow occupants to evacuate. A delay in the spread of fire can save lives as well as damage to a property. Fire rated plasterboard are easy to identify due to their pink colour.

Vapour Barrier Plasterboard

Vapour barrier plasterboards featured a thin metallic foil layer. This layer is fixed onto the rear side of the sheet. The metallic foil helps to prevent warm vapours to pass into the board itself. This specialist type of board can help to keep a space warm. They are often used in the underside of roofs and decks. Vapour barrier plasterboards are ideal for use where high vapour resistance is essential. This includes areas such as pitched roofs in loft conversions.

What size and thickness are plasterboards available in?

Plasterboards are available in a variety of sizes in thicknesses. The most commonly used thicknesses for standard plasterboards are 12.5mm or 15mm. For insulated plasterboards, a common thickness is 37.5mm, which consists of 12.5mm plasterboard thickness and 25mm insulation. When it comes to dimensions, 2400mm x 1200mm are the most popular. This gives the board a total coverage of 2.88m2. On our website, you can also find other dimensions such as 3000mm x 1200mm or 1800mm x 900mm, however these are not as popular. The size and thickness you purchase will depend on your specifications, which is usually determined by an architect. Our standard wallboard is available in both square and tapered edge whereas our specialist boards are only available in tapered edge.

Where can plasterboards be installed

Plasterboard is widely used due to its versatility. Most commonly it used for creating partition walls, however it can also be used in suspended ceilings. Specialist plasterboard such as moisture panels will often be found in areas such as bathrooms. Fire rated plasterboard will be found in areas where fire risk is a concern. Overall, plasterboard can be used in partition walls, suspended wall ceilings, separating walls and shaft wall systems.

*Above you can see plasterboard being installed in a suspended ceiling system.

*Above you can see plasterboard being installed in a suspended ceiling system.

What are the advantages of installing plasterboard?

There are many advantages to installing plasterboard. It is widely used in the UK, and mainly due to the benefits below:

- They are cost effective

- They can be easily replaced or repaired

- They can be recycled

- Plasterboard is easy to install

- Plasterboard can be painted or decorated

- They have a smooth finish

- They are easy to cut

When it comes to cutting, the process is easy. You need to simply measure and mark the cut you wish to make. We suggest using a sharp plasterboard knife to mark a cut. You can use a saw to cut along the marked line. If your scored line is clearly defined then you can snap the plasterboard off at this line for a clean cut.

Plasterboard is lightweight and easy to handle, which is another reason it is so popular.