| Dimensions | 1200 × 455 mm |

|---|---|

| Brand |

Isover |

| Thickness |

100mm |

| Material Type |

Glass Mineral |

| Pieces Per Pack |

20 |

| Sales Unit |

Pallet |

| Unit Coverage |

87.4m2 |

| Manufacturers Reference |

5200673467 |

| Thermal Conductivity |

0.034W/mK |

| Fire Rating |

Euroclass A1 |

| Edge Type |

Square |

| Facing |

Glass Mineral Wool |

| Product Range |

Isover Cavity Wall Slabs |

Please note this item is a Special Order – see terms and conditions

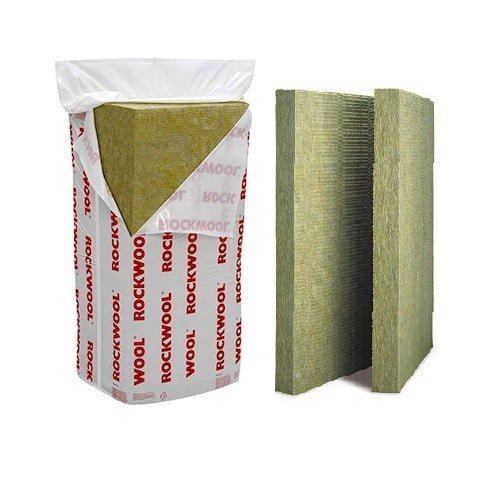

100mm Isover Cavity Wall Slabs 34 (CWS 34) – 1200 x 455mm – 87.4m2 pallet

Request your delivery date in checkout

on orders over £350 +VAT

£967.64 Original price was: £967.64.£879.67Current price is: £879.67. ex VAT

In Stock

Please note this item is a Special Order – see terms and conditions

EXCELLENTTrustindex verifies that the original source of the review is Google. Easy to purchase at reasonable prices. Great deliveryTrustindex verifies that the original source of the review is Google. Excellent service - Large order on pallets delivered to my door at the best price I could find - Thank youTrustindex verifies that the original source of the review is Google. Great price and service. Was kept up to date with delivery, driver helped me get the material where it needed to be and even got a curtesy text from the firm the following day to make sure everything was ok. 100% would use and again and recommend.Trustindex verifies that the original source of the review is Google. good service, fast delivery and communicationTrustindex verifies that the original source of the review is Google. Great prices, easy and communicative with the deliveryTrustindex verifies that the original source of the review is Google. Great price. Great delivery of PIR plasterboard. Top driver too, placed exactly where I wanted them. Packed well with multiple plastic wrap layers so no chance of the boards getting wet in bad weather. No damages. Didn't let me down. Thanks!Trustindex verifies that the original source of the review is Google. Excellent service from a well priced company. I’ll be using this company again for insulation.Trustindex verifies that the original source of the review is Google. I was surprised how quick from ordering to delivery took, plenty of delivery updates on the day and a phone call when they were close by. Delivery man was keen to help and position the boards where needed as well. Cant fault them.Trustindex verifies that the original source of the review is Google. Well a great transition from these guys was the cheapest online yet the quality is fantastic delivery time short and on time delivery guys efficient and polite thanks James and the gang my go to for insulation 👍Trustindex verifies that the original source of the review is Google. As others have said, friendly and helpful, super smooth delivery, and the best price I could find online. Great customer service, and really communicative about the delivery, including having a real-time tracker. Would not hesitate to recommend.

100mm Isover Cavity Wall Slabs 34

Isover Cavity Wall Slabs 34 100mm offer high-quality insulation and superior thermal performance for cavity wall construction. They are made from eco-friendly and sustainable glass mineral wool, which effectively reduces heat loss and enhances energy efficiency in buildings.

100mm Isover Cavity Wall Slabs 34 are easy to install and save construction time and costs. These slabs can be easily cut to size and shape and do not require any additional fixings, fitting snugly into standard wall cavities. This ensures secure and long-lasting insulation.

The benefits of using 100mm Isover Cavity Wall Slabs 34

100mm Isover Cavity Wall Slabs 34 provide excellent thermal performance with a thermal conductivity of 0.034 W/mK, offering outstanding insulation against heat loss. This makes them suitable for use in new and retrofit projects, reducing energy bills, and improving occupants’ comfort levels. They are also fire-resistant, non-combustible, and have a Euroclass A1 fire rating, ensuring maximum safety.

Isover Cavity Wall Slabs 34 100mm are durable and long-lasting, resistant to moisture, mould, and rot, and maintain their thermal and acoustic properties in damp conditions. This makes them ideal for buildings located in areas with high levels of rainfall or humidity.

100mm Isover Cavity Wall Slabs 34 are cost-effective and competitively priced, providing excellent thermal and acoustic performance, reducing energy bills, and improving comfort levels, making them a fantastic investment for construction projects.

How to install Isover Cavity Wall Slabs 34 100mm

If you’re planning to install Isover Cavity Wall Slabs 34 100mm, there are some simple steps to follow to ensure a successful installation. Firstly, you need to prepare the cavity by cleaning it and checking that it’s the right width to fit the 100mm thick slabs.

Next, you need to cut the slabs to the correct size using an insulation knife or saw. Once the slabs are cut, you can place them into the cavity, starting from the bottom and working your way up.

Ensure that the slabs fit snugly into the cavity and that there are no gaps or spaces between them. In most cases, it’s not necessary to secure the slabs in place. However, if required, you can use retaining clips or battens.

It’s important to seal any joints between the slabs using a suitable insulation tape or sealant to prevent heat loss and improve the overall insulation performance of the wall. Once the slabs are in place, you can finish the wall as required, either by adding plasterboard or other cladding material. Make sure that any finishing material is compatible with the insulation used.

Remember to always follow the manufacturer’s instructions carefully and wear appropriate personal protective equipment, such as gloves and a dust mask, when handling insulation materials. If you’re unsure about any aspect of the installation, seek professional advice or assistance.

How to correctly store 100mm Isover Cavity Wall Slabs 34

Proper storage of Isover Cavity Wall Slabs 34 100mm is crucial for maintaining their quality and effectiveness. To ensure the insulation material remains undamaged, it should be stored in a dry and well-ventilated area, away from sources of moisture or dampness. Exposure to moisture can compromise the integrity of the slabs and reduce their effectiveness.

During storage, handle the slabs with care to avoid any damage to their structure or integrity. Do not stack them too high, as this can cause compression and deformity. Store the slabs horizontally on a flat surface and avoid placing them on their edges or corners.

To protect the slabs from external elements like dust or debris, it is recommended to keep them in their original packaging until ready for use.

By following these guidelines, you can ensure that the Isover Cavity Wall Slabs 34 100mm are correctly stored and ready to provide optimal insulation for your home or building when needed.

What are 100mm Isover Cavity Wall Slabs 34, and what are they used for?

They are a type of insulation material designed to fit into the cavity walls of buildings. These slabs are used to provide thermal insulation to the walls, reducing heat loss and helping to improve the energy efficiency of buildings.

How do I install Isover Cavity Wall Slabs 34 100mm?

Installation is a straightforward process. The slabs are cut to size using an insulation knife or saw and then placed into the wall cavity. The slabs should fit snugly into the cavity, with any gaps or spaces between them sealed with insulation tape or sealant.

Can I use Isover Cavity Wall Slabs 34 100mm in all types of wall cavities?

Isover Cavity Wall Slabs 34 are suitable for use in standard wall cavities. However, they may not be suitable for use in narrow or irregular cavities, in which case, an alternative insulation material may be required.

How do I store Isover Cavity Wall Slabs 34 100mm correctly?

They should be stored in a dry and well-ventilated area, away from moisture or any sources of dampness. It is recommended that the insulation material be kept in its original packaging until it is ready for use.

Are Isover Cavity Wall Slabs 34 100mm fire-resistant?

Isover Cavity Wall Slabs 34 are classified as Euroclass A1 non-combustible, meaning they have the highest level of fire resistance.

What are the benefits of using Isover Cavity Wall Slabs 34 100mm?

The use of Isover Cavity Wall Slabs 34 provides several benefits, including improved thermal insulation, reduced heat loss, and improved energy efficiency of buildings. The insulation material also provides sound insulation and is fire-resistant.

| Dimensions | 1200 × 455 mm |

|---|---|

| Brand |

Isover |

| Thickness |

100mm |

| Material Type |

Glass Mineral |

| Pieces Per Pack |

20 |

| Sales Unit |

Pallet |

| Unit Coverage |

87.4m2 |

| Manufacturers Reference |

5200673467 |

| Thermal Conductivity |

0.034W/mK |

| Fire Rating |

Euroclass A1 |

| Edge Type |

Square |

| Facing |

Glass Mineral Wool |

| Product Range |

Isover Cavity Wall Slabs |

| Dimensions | 1200 × 455 mm |

|---|---|

| Brand |

Isover |

| Thickness |

100mm |

| Material Type |

Glass Mineral |

| Pieces Per Pack |

20 |

| Sales Unit |

Pallet |

| Unit Coverage |

87.4m2 |

| Manufacturers Reference |

5200673467 |

| Thermal Conductivity |

0.034W/mK |

| Fire Rating |

Euroclass A1 |

| Edge Type |

Square |

| Facing |

Glass Mineral Wool |

| Product Range |

Isover Cavity Wall Slabs |

Hassan –

Shame they only sell this in pallets as i only need 6 packs – good price though

Michael –

I recently installed the 100mm Isover Cavity Wall Slabs in my home, and I couldn’t be happier with the results!

Michael –

Delivered exactly when promised

Vladimir –

Really happy with the product and the driver Darren was amazing

Samuel –

Reviewer didn’t leave any comments

Farah –

High-quality and easy to install. Noticeable improvement

Lungelo –

Installation was a breeze, and the insulation is outstanding. Highly recommended!

Chukwuemeka –

Fast delivery and reliable service.

james –

overall great service and amazing delivery team.