Ecotherm Eco Versal

The ‘Versal’ in Eco-Versal stands for the versatility of the product itself. Ecotherm Eco Versal is a 5 in 1 product. This means it can be used in 5 different application types. These multipurpose application boards are perfect for use in walls, floors, ceilings and roofs. The boards are in thicknesses ranging from 25mm to 150mm. In addition to this, they provide a thermal conductivity of just 0.022W/mK. The insulation boards are extremely durable. The polyisocyanurate core of Eco-Versal boards has a low moisture absorption capacity.

We offer are very best price on Eco Versal boards. Order online and discover why Trade Insulations is the top supplier of trade price insulation.

Showing all 15 results

100mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £39.99.£28.99Current price is: £28.99. ex VAT30mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £21.39.£12.99Current price is: £12.99. ex VAT40mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £24.65.£16.45Current price is: £16.45. ex VAT60mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £31.15.£21.99Current price is: £21.99. ex VAT70mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £34.89.£23.99Current price is: £23.99. ex VAT90mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £42.95.£29.99Current price is: £29.99. ex VAT80mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £39.40.£26.99Current price is: £26.99. ex VAT110mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £55.20.£37.99Current price is: £37.99. ex VAT130mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £59.40.£42.99Current price is: £42.99. ex VAT140mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £62.50.£44.00Current price is: £44.00. ex VAT25mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £18.29.£11.40Current price is: £11.40. ex VAT50mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £25.15.£16.99Current price is: £16.99. ex VAT150mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £61.50.£44.99Current price is: £44.99. ex VAT75mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £34.99.£24.25Current price is: £24.25. ex VAT120mm Ecotherm Eco Versal Insulation Board (1200x2400mm) 2.88m2

Original price was: £51.99.£36.99Current price is: £36.99. ex VATEcotherm Eco-Versal

EcoTherm Eco-Versal Insulation Boards are a versatile solution designed to enhance insulation in a variety of construction projects. These boards are engineered to provide exceptional thermal performance for different insulation requirements.

Eco Versal boards can be applied in various contexts, such as roofs, walls, ceilings and floors, making them adaptable to a wide range of construction and renovation projects. They effectively minimise heat loss, improving energy efficiency and interior comfort.

Sustainability is a core principle of EcoTherm, and the Eco-Versal boards boast excellent performance. They are designed for long-term use, reducing environmental impact.

These boards are user-friendly and lightweight, simplifying the installation process. They may also come with relevant certifications and adhere to industry standards, ensuring dependable and safe performance. All relevant data sheets can be found on our product pages.

By reducing energy consumption and enhancing insulation, Eco-Versal boards can lead to cost savings in heating and cooling over time, offering a cost-effective insulation solution.

Whether you're looking to enhance energy efficiency in your home or create a comfortable environment in a commercial setting, EcoTherm Eco-Versal Insulation Boards provide a versatile, sustainable, and high-performance solution. Make an informed choice with EcoTherm Eco-Versal boards.

Key Features:

- Resistance to solvents, fungi & rodents

- Extremely durable

- Sustainable

- Excellent thermal insulation

- Better dimensional stability

- Lightweight but sturdy

- Multi-purpose insulation applications

Ecotherm Eco Versal Insulation Boards

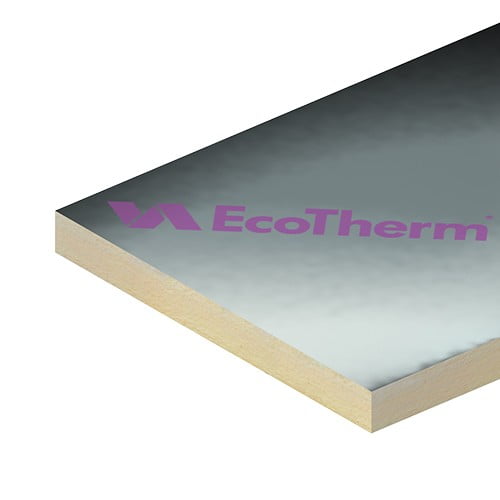

The Ecotherm insulation boards themselves are lightweight and easy to cut, handle, and install. In fact, the boards can be cut easily by using a fine-toothed saw. When installing the boards, ensure that you measure and mark them if necessary. It is recommended that the boards are cut on a higher surface providing room for the saw to cut through the board. When cutting the boards, they can produce particles that should not be inhaled and can irritate the skin and eyes. The recommended gear is protective clothing, a face mask, eye goggles, and gloves. The boards can also be cut with a knife by scoring one side of the board, snapping the board over a hard edge, and then scoring the other side of the facing. These boards have a thin profile and excellent thermal properties considering this.

Ecotherm Versal Insulation Boards can be installed in a range of applications. These include:

- Floors including underfloor heating systems

- Pitched roofs and cold flat roofs

- Walls, including timber frame walls, solid walls, and dormer cheeks

- Roofs, including ceilings and room-in-the-roof applications

Eco Versal boards are available in thicknesses ranging from 25mm up to 150mm. We always suggest you speak to a building professional or architect for advice on which product is best suited to your project. We cannot give advice on this as every build and requirement is bespoke. A list of each thickness can be found below:

- 25mm EcoTherm Insulation Board

- 30mm EcoTherm Insulation Board

- 40mm EcoTherm Insulation Board

- 50mm EcoTherm Insulation Board

- 60mm EcoTherm Insulation Board

- 70mm EcoTherm Insulation Board

- 80mm EcoTherm Insulation Board

- 90mm EcoTherm Insulation Board

- 100mm EcoTherm Insulation Board

- 110mm EcoTherm Insulation Board

- 120mm EcoTherm Insulation Board

- 130mm EcoTherm Insulation Board

- 140mm EcoTherm Insulation Board

- 150mm EcoTherm Insulation Board

Eco Versal Floor Insulation

EcoTherms Eco Versal are multi purpose boards, which means they can be used in a variety of applications. This includes in floor applications. Many people choose Eco-Versal as the floor insulation of their choice.

The exceptional thermal performance of Ecotherms Eco Versal ensures that heat loss is effectively minimised when applied in floors. This feature creates a consistent and comfortable indoor temperature, ultimately leading to cost savings on heating and cooling over time.

The lightweight nature of Eco-Versal boards makes them easy to handle and install, reducing both time and install costs. Their adaptability means they can be effectively used in various floor types, from concrete to suspended timber.

In addition to their thermal benefits, Eco Versal boards can reduce sound transmission. This is especially valuable in multi-story buildings where reducing noise transmission between floors is essential for a quieter and more pleasant environment. Please note that Eco Versal boards are not specifically designed as acoustic insulation.

Eco-Versal boards are durable to help maintain long-lasting performance and maintaining their insulating properties. In addition to this, we provide our best price on Eco-Versal, which means that the insulation is very cost effective when you purchase from us.

For floor insulation projects, EcoTherm Eco-Versal Insulation Boards offer an efficient, versatile, and sustainable solution that ensures a comfortable and cost-effective space while promoting energy efficiency and environmental sustainability. Whether it's a residential or commercial project, choosing Eco-Versal boards for floor applications is a wise investment in insulation performance.