Kingspan TP10 Insulation Board (Kingspan Thermapitch)

Kingspan Thermapitch TP10 is a fibre free, rigid sheet of compact material with high-performance CFC/HCFC–free polyisocyanurate (PIR) based formulation. Its core is faced on both sides with a low emissivity composite foil facing which is used to insulate spaces in ventilated or unventilated pitched roofs and under tiles or slabs. TP10 is a general purpose board, which is branded by Kingspan for use in pitched roofs. The make up of the board itself is the same as other Therma products, such as TW55 or TF70. This means it can be use in a number of applications.

Showing all 16 results

100mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 8.64m2 pack

Original price was: £155.29.£119.33Current price is: £119.33. ex VAT25mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 34.56m2 pack

Original price was: £199.99.£174.15Current price is: £174.15. ex VAT75mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 11.25m2 pack

Original price was: £179.22.£128.46Current price is: £128.46. ex VAT50mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 17.28m2 pack

Original price was: £168.00.£143.22Current price is: £143.22. ex VAT90mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 8.64m2 pack

Original price was: £182.49.£118.24Current price is: £118.24. ex VAT120mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 5.76m2 pack

Original price was: £144.89.£96.74Current price is: £96.74. ex VAT70mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 11.52m2 pack

Original price was: £183.83.£123.84Current price is: £123.84. ex VAT150mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 5.76m2 pack

Original price was: £195.20.£120.94Current price is: £120.94. ex VAT140mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 5.76m2 pack

Original price was: £159.74.£117.71Current price is: £117.71. ex VAT40mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 23.04m2 pack

Original price was: £230.26.£177.38Current price is: £177.38. ex VAT30mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 28.8m2 pack

Original price was: £304.70.£182.74Current price is: £182.74. ex VAT80mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 11.52m2 pack

Original price was: £205.70.£139.74Current price is: £139.74. ex VAT110mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 8.64m2 pack

Original price was: £230.26.£150.49Current price is: £150.49. ex VAT125mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 5.76m2 pack

Original price was: £157.30.£107.49Current price is: £107.49. ex VAT60mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 14.4m2 pack

Original price was: £208.74.£144.52Current price is: £144.52. ex VAT20mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 43.2m2 pack

Original price was: £316.80.£214.99Current price is: £214.99. ex VATKingspan TP10

Kingspan TP10 is a high performance PIR board. It is available in a variety of thicknesses and boasts excellent thermal values. TP10 can be easily cut and installed. TP10 is branded by Kingspan for use in pitched roof applications, however this product is the same as other 'Therma' products, such as Thermawall and Thermafloor. This means that it can actually be used in multiple applications such as roofs, walls and floors. The packaging remains the same for TP10, TW55 and TF70 whereby they are all listed.

Kingspan TP10 is suitable for new build or retrofit projects. It is a reliable PIR board manufactured by Kingspan. The different thicknesses available means that you can find the ideal thickness for your project. In addition to this, Kingspan TP10 boasts an excellent reputation for efficiency.

Thermapitch TP10

The reason Kingspan TP10 is called Thermapitch is because Kingspan have branded their PIR 'Therma' products into categories. This can help reassure the buyer in knowing they have the right product for the job. Kingspan market TP10 insulation as a product that is used in pitched roofs and attic / loft spaces. In reality, Kingspan TP10 can be used in all the same applications as Thermafloor or Thermawall.

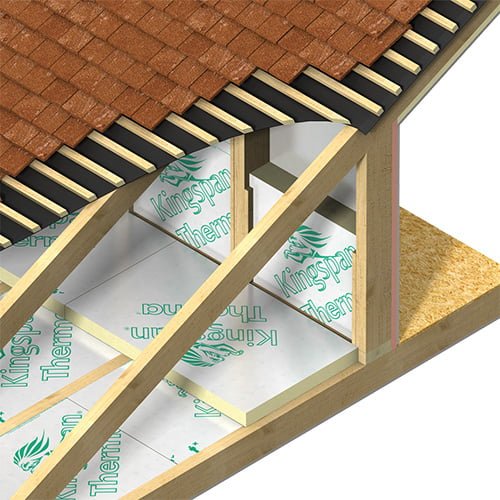

When used in a pitched roof, it can help reduce heat loss through the roof itself. This can help keep heat in therefore reducing the need for additional heating. This means the homeowner can keep their house heated for far less energy. This makes Kingspan TP10 an extremely cost effective product, which can also help you to reduce your carbon footprint. In addition to this, Kingspan Thermapitch TP10 is not susceptible to sagging over time. You can find all relevant data sheets and certificates on our product pages. This includes robust details for Part E of the Building Regulations (England & Wales).

Why use Kingspan TP10?

There are multiple reasons as to why Kingspan TP10 is a great choice for almost any building project. Below are a few key features of Kingspan TP10.

- Suitable for general use

- Resistant to the passage of water vapour

- CFC / HSCFC free

- Features low emissivity foil facings

- BBA Approved & certified to BES 6001

- Rated A+ On The Green Guide Rating

- Manufactured to ISO 14001

In addition to this, Kingspan TP10 is lightweight and therefore easy to deliver, handle and install. Builders and DIY enthusiasts alike use Kingspan TP10 on a daily basis. The foil facing of this PIR board, means that it prevents a build up of excessive moisture. A build up of moisture can be problematic as it could cause damp and condensation forming. Furthermore, TP10 is a durable product which is designed to last the lifespan of the home or commercial building it is installed in.

How to correctly store Kingspan TP10

If you have to store TP10, then we advise that you keep it in a dry and secure environment. Harsh weather conditions can cause damage to the board and therefore reduce the effectiveness of the product itself. We suggest that you keep the product stored inside if you can. If this is not an option then make sure that the product is well covered over with a waterproof material to prevent rain from getting on the boards. If the boards do get slightly damp, make sure you clean and dry them before installing them.

When storing TP10 ensure that they are not stacked too high on top of each other. Also do not place heavy objects on the boards themselves. This is because too much pressure can cause the boards to damage. Ensure that TP10 insulation is kept on a flat level surface.

Furthermore, Kingspan TP10 is a sought after product, which means that it is often targeted for theft. Please ensure that the boards are kept in a safe and secure environment to stop and deter thieves.

Kingspan Thermapitch Insulation Data sheets

Below you can find all relevant data sheets as well as certification for Kingspan TP10.

Kingspan TP10 Brochure

Kingspan Thermarange BES-6001 Certificate

Kingspan Declaration Of Performance (TP10, TF70, TW55)

How to install Kingspan TP10 between rafters?

Installing Kingspan TP10 insulation is identical to the install process of any other PIR board in a pitched roof. Below we have written a brief guide on how to install Kingspan PIR.

Before you begin, you will need a few items. These include:

- PPE such as a face mask, goggles or protective clothing. This is due to small fibers produced when cutting which can sting the eyes and irritate the skin.

- Either a fine-toothed saw or sharp utility knife.

- A Tape measure and pencil

When installing TP10, ensure the work space is dry and clear from any contaminants.

Installing insulation between rafters

Firstly measure the section in which you wish to fit the insulation. Use a tape measure and mark the insulation to match the section you wish to fit insulation in.

If the insulation needs cutting down to size, simply use a hand saw to make a direct cut. You can also score the board with a utility knife and snap the board down your score line.

Once you have the right size, your insulation can be slotted and fixed into the rafters. Ensure that it is snug but not pushing against the rafters. You can use a flat block of wood to pat against the rafters to check that the insulation is secure and in place.

Some people choose to use expanding foam or wool to fill any gap in uneven rafters. Measure the rafters in order to lay another sheet of insulation board vertically across the horizontal insulation.

Fasten suspension rods spaced 600mm apart to the rafters using a screwdriver. Lay another sheet of insulation on the suspension rods vertically. Immediately fasten the suspension clips onto the suspension rods.

Attach metal furring profiles to the suspension clips and secure them with double-sided aluminium tape.

Peel the back of the tap and apply a vapour control layer across the metal profiles. Add another layer of tape around all edges including the roof and floor and spaces between layers.

Kingspan products are designed for use in over, under and between pitched roof rafters in lofts. There is a difference between 'warm roof' and 'cold roof' installations. The following helpful guide on the Kingspan website can help provide additional help – View Guide

Cheap TP10

We offer our best price on TP10 directly on our website. At Trade Insulations, we believe in providing top brands for trade prices. You don't even need to be in the trade to get trade prices. A lot of our clients use us for DIY projects because we can offer a quality product at a lot lower price point.

We don't sell seconds or defect boards. All of the insulation on our website is brand new. As a dedicated supplier of insulation, we make savings by purchasing insulation in bulk. Instead of pocketing the savings, we pass this on directly to the customer. Why pay more for insulation when you could use Trade Insulations?