At Trade Insulations, we offer only our best prices on Knauf Dritherm Cavity Slabs. We sell the full range of Knauf Dritherm. This includes Dritherm 32, Dritherm 34 and Dritherm 37. Dritherm by Knauf are cavity slabs designed for use in external masonry cavity walls. If you need any assistance with buying our Dritherm cavity slabs then get in touch.

Knauf Dritherm Cavity Slabs

Showing all 12 results

What are Dritherm Cavity Slabs?

Dritherm Cavity Wall Slabs are made from glass mineral wool and are designed for cavity wall applications. Dritherm Cavity Wall Insulation slabs are manufactured using Knauf's innovative ECOSE technology. This means the slabs are made using a binder that comes from a rapidly renewable biomaterial rather than petroleum. The manufacturing process uses up to 70% less energy to make. This means that the finished product is soft like cotton wool rather than scratchy or itchy. Traditionally glass mineral wool products are known to be very itchy, however, Knauf Dritherm Slabs are not.

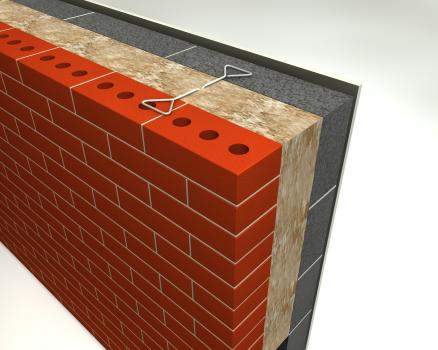

Knauf Dritherm Slabs are designed for use in cavity walls. The insulation slabs by Knauf are semi-rigid or rigid. They boast several properties such as being water repellent and non-combustible. Dritherm Cavity Wall Slabs achieve an A1 non-combustible classification. The slabs themselves are made from glass mineral wool and offer excellent thermal performance. They are to be used in masonry cavity external walls and can be used in buildings up to 12m in any exposure zone. In addition to this, they can be used in multi-story applications up to 25 meters tall.

A big cause of heat loss in buildings is down to cavity walls being empty. Empty cavity walls can cause air movement as well as heat loss. This is why it is important to fill the gaps to reduce energy bills and retain heat in a building. Dritherm Cavity Wall Insulation Slabs are designed to do just this. On our website, you can find the full range of Dritherm Cavity Slabs. These high-performance slabs are designed to use between masonry cavity walls and can be used in both commercial and residential buildings.

Cheap Dritherm Cavity Slabs

You will find cheap Dritherm Slabs on our website. We believe in offering trade prices to the public, which means we can offer our best available price on all insulation slabs. If you are looking for cheap Dritherm cavity slabs, use our website to find a great deal. We take pride in being able to give back to the customer by offering rock bottom prices. At Trade Insulations, our motto is top brands at trade prices.

How to install Dritherm Cavity Slabs

Begin the first stage of masonry construction for one leaf by building up the initial layer and incorporating the first row of ties just above the Dritherm Cavity Slabs. Ensure to clean off any excess mortar (snots) from the ties or cavity tray to maintain a neat and secure structure.

Place the Dritherm Cavity Slabs against the masonry leaf. If needed, cut them to fit the course appropriately. The slabs should extend below the floor insulation level to minimize thermal bridging and prevent any capillary action. Ensure that the Dritherm Cavity Slabs align with the placement of wall ties for a secure and effective installation.

No mortar should remain in the cavity when it comes to cavity wall applications. Take care to keep batt joints closely butted. Knauf recommend to use cavity boards to help keep the top edges of batts clean.

You can start construction with either the inner or outer leaf. If starting with the inner leaf, create a trough no deeper than one brick at horizontal joints of Dritherm Cavity Slabs. Ensure that mortar joints are flush inside the cavity, and remove any mortar droppings before fitting the next batt.

Additional Installation Notes

Cavities are insulated by completely filling the cavity. It is worth noting that the cavity thickness must be fit to the size of the cavity. Do not compress or squash thicker slabs into narrow spaces. If Dritherm needs to be cut then ensure it is neatly done using an insulation saw or knife. Do not distort the mineral wool when cut as this may affect performance.

Knauf Insulation and NHBC advise maintaining a uniform cavity thickness during construction. We discourage the use of rough stone. If natural stone is specified, it should be cut to face to ensure a uniform and parallel cavity. If this recommendation isn't followed, an alternative option is using a backing block in the outer leaf.

The cavity insulation needs to be tightly butted to prevent big gaps. Gaps can affect thermal performance and also create routes for dampess and condensation, which is not ideal.

Dritherm 32

Dritherm 32 by Knauf are non-combustible cavity insulation slabs. These glass mineral wool slabs are manufactured using our revolutionary ECOSE® technology. Knauf Dritherm 32 slabs feature a water-repellent additive, which has a 50-year guarantee on resisting the transmission of water. Dritherm 32 is designed for use in external masonry cavity walls to provide a full-fill insulation solution, which is to be installed as walls are being built. Knauf Dritherm 32 Cavity Slabs represent no known threat to the environment and have zero ODP and zero GWP. The slabs are rot-proof, odourless, non-hygroscopic, do not sustain vermin and will not encourage the growth of mould, fungi, or bacteria.

Knauf Dritherm 32 Cavity Slabs are 455mm wide, which is suited to standard vertical wall tie spacings allowing a closed joint with adjacent slabs. Earthwool DriTherm 32 Cavity Slabs are lightweight and easily cut to size. This makes them easy to handle and install.

Dritherm 37

Dritherm 37 has a thermal conductivity of 0.037 W/mk and is a perfect solution for cavity walls. Like all other Dritherm products, it is easy to install and is cost effective. They boast good resistance to water and have a water repellent added to the product to enhance its performance. Dritherm 37 is the standard cavity slab whereas Dritherm 34 is the super cavity slab. Dritherm 32 is the ultimate cavity slab of the range. As mentioned previously, the differing factor is the thermal conductivity rates. Picking the right Dritherm product depends on your individual needs and requirements. If you are unsure of which Dritherm product to choose, consult a building professional or architect.

Dritherm 37 is free from harmful gases (CFC and HCFC) and are easy to cut to size when required.

Dritherm Cavity Slab FAQs

Below you will find the answers to some frequently asked questions that we get about Dritherm Cavity Slabs.

What is the difference between Dritherm Slabs?

You may be wondering what is the difference between Dritherm 32, Dritherm 34 and Dritherm 37. The numbers stated on the product actually refer to the product's thermal conductivity value. For example, Dritherm 32 slabs have a thermal conductivity of 0.032 (W/mK) whereas Dritherm 34 has a thermal conductivity of 0.034 (W/mK). The “Dri” in Dritherm refers to their water repellent additive whereas the “Therm” in Dritherm refers to its excellent thermal performance. Knauf Earthwool Dritherm Cavity Slabs are cut at 455mm wide. This is in line with standard wall tie spacings, which produce a neatly closed joint when used with adjacent slabs. The use of Dritherm Slabs can eliminate air gaps.

Which is better Dritherm 32 or Dritherm 37?

When comparing Dritherm 32 and Dritherm 37, the major difference between the two is the thermal conductivity. Dritherm 32 has 0.032 (W/mK) and Dritherm 37 has 0.037 (W/mK). This means Dritherm 37 rates higher for thermal conductivity. That being said, the slab you use is really down to the project and application. Your architect may be able to let you know which product is more suitable depending on your requirements. We can also offer your advice if you get in touch with us.

Are Dritherm Cavity Slabs Fireproof?

Knauf Dritherm 32, Dritherm 34 and Dritherm 37 are rated with the best possible Euroclass A1 reaction to fire classification. The Euroclass scale is rated from F, which is combustible to A1, which is classed as non-combustible. All Dritherm products are rated A1 and therefore non-combustible. Dritherm Cavity Slabs boast excellent fire protection and can help to minimise the spread of fire. This can potentially save lives as well as minimise building damage.

What are the benefits of using Dritherm Cavity Slabs

Dritherm cavity slabs are designed to fill cavity wall gaps and therefore reduce air movement and heat from escaping. A big advantage of using Knauf Insulation Dritherm Cavity Slabs is that they are uniquely made to be compatible with vertical wall ties. This eliminates the need for retaining discs. The slabs themselves are very easy to install and are also rigid. This means you don't need expensive equipment to install it. The product itself boasts good levels of thermal resistance.

Dritherm Cavity Slabs are made by Knauf, who are environmentally conscious. Knauf Dritherm Cavity Slabs are made using ECOSE technology. This manufacturing technology means that the slabs are made using a natural biomaterial instead of petroleum. Dritherm Cavity Slabs are up to 70% less intensive to create than using typical binders. In addition to this, the product itself boasts excellent thermal performance. This means that the slabs can reduce heat loss in a building, which therefore reduces the energy needed to heat a home. Dritherm Cavity Slabs are eco-friendly and classified as zero ODP and zero Global Warming Potential.

Are Dritherm Cavity Slabs Waterproof

Dritherm Slabs feature a water repellent additive that helps keep them dry. The “Dri” in Dritherm is actually a reference to the water repellent additive that is in the product itself. That being said, Knauf Cavity Slabs are great at repelling water but they are not entirely waterproof. Many people confuse water resistance with waterproofing.

Dritherm Cavity slabs have a good water vapour resistivity of 5.00MNs/g.m. In addition to this, they are non-hygroscopic, which means they do not absorb and retain moisture. The water-resistant properties of the Knauf Dritherm range mean that the slabs also benefit from no rot, vermin or fungus.

What is Full Fill Insulation?

Dritherm Cavity Slabs are used to fully fill empty cavity spaces. This is different from partial fill applications, which are achieved using PIR Insulation Boards. PIR boards are used in cavity spaces to create an air gap rather than fully fill the gap. Dritherm Cavity Slabs fully fill the gap using rigid slabs. The simple difference between partial fill and full fill is that partial fill will only partially fill the gap whereas full fill will fully fill the gap.

Can Dritherm Cavity Slabs Be Cut?

Yes, the slabs are designed to be easily cut to size. The cavity slabs themselves are very lightweight and can be cut using a sharp serrated knife. We advise that you wear appropriate clothing and PPE when cutting. This includes cut resistant gloves as well as protective eyewear. If you are concerned about safety precautions then we would always recommend that you consult with a professional.

How to store and handle Knauf Cavity Slabs

To maintain the quality of DriTherm Cavity Slabs, proper storage and handling are essential. The slabs should be kept clean and free from damage. They are supplied in polythene packs or shrink-wrapped pallets, which provide short-term protection. Once the outer hood is opened, it's recommended to store the packs under cover.

For extended protection on-site, two options are suggested: either store the product indoors or keep it under cover and elevated off the ground to prevent contact with ground moisture. Leaving the slabs exposed to the elements for a prolonged period should be avoided. Additionally, protection from direct sunlight is crucial.

To ensure the slabs' longevity and optimal performance, they must be stored in a dry and flat position. Following these guidelines will help maintain the effectiveness of Dritherm Cavity Slabs during their use in construction.

Dritherm Cavity Slabs are designed to be lightweight and convenient to handle. However, caution should be taken to avoid crushing the edges or corners, as this could affect their performance.

For safety during cutting and handling, it is recommended to wear dust masks, gloves, and long-sleeved clothing.

During construction, it's essential to protect exposed areas of the slabs from the elements. At the end of each day's work or in heavy rain, make sure to cover the exposed slabs with polyethylene covers. This protective measure will prevent the slabs from becoming saturated and maintain their effectiveness in insulation.

If you are looking for Dritherm insulation, then look no further. We offer our very best price and pride ourselves on outstanding service.