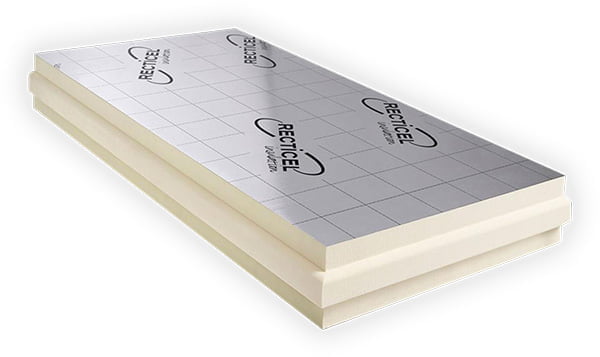

Recticel Eurowall Plus Full Fill Cavity Wall Insulation Boards

Recticel Eurowall+ boards are a specialist high-performance insulation material, designed for the application of cavity walls to improve the thermal quality within commercial or residential buildings. This board consists of a polyisocyanurate (PIR) core with each side bonded to low emissivity foil facings to improve thermal conductivity. Recticel Eurowall+ boards have tongue and groove cut edges to ensure boards can be interlocked tightly during application.

Showing all 3 results

Recticel Eurowall Plus Full Fill Cavity Wall Insulation Board (1190mm x 450mm) – 115mm – 4.32m2 pack

Original price was: £159.50.£96.12Current price is: £96.12. ex VATRecticel Eurowall Plus Full Fill Cavity Wall Insulation Board (1190mm x 450mm) – 140mm – 4.32m2 pack

Original price was: £181.50.£120.96Current price is: £120.96. ex VATRecticel Eurowall Plus Full Fill Cavity Wall Insulation Board (1190mm x 450mm) – 90mm – 5.4m2 pack

Original price was: £159.50.£96.12Current price is: £96.12. ex VATThe Eurowall plus boards are 1200mm by 460mm (including tongue and groove joints) with thicknesses between 90mm and 140mm with a thermal conductivity of just 0.022W/mK. This product is extremely durable and when installed correctly can provide reliable long term thermal performance that will continue to last for the entire lifetime of the building. Eurowall + helps to provide a more temperature-controlled environment meaning warmer winters and cooler summers. The boards are lightweight, tough, slightly flexible, and easy to cut, handle, and install.

KEY FEATURES:

- Available for new builds or refurbishments

- Excellent thermal performance

- Range of thicknesses to suit project needs

- No degradation or deterioration if exposed to moisture

- Tongue and Groove finish on all sides

- Good compressive strength

- Quick installation

- CFC and HCFC free

- Durable and long lasting

Cutting:

Eurowall plus can be easily cut using a fine-toothed saw by measuring and marking the board and placing the board on a higher surface to allow the saw to cut though. The boards can also be cut with a sharp knife by scoring one side of the board, snapping over a hard edge, and scoring the other side.

Packaging and storage:

Eurowall+ should be stored indoors and on a flat surface. If indoor storage is not an option, ensure the boards are protected with the correct weatherproofing materials. Although the boards are rigid, excess weight and standing on the boards should be avoided as the boards can begin to crumble from the inside due to too much pressure on the boards core.

Environment:

Correctly insulating your home or office space can mean saving you money on up to 30% of your energy bills whilst creating a more sustainable environment. By reducing the heat levels escaping your property, you are contributing to the reduction of climate change and global warming.

Recticel Eurowall + can be installed in a range of methods. These methods include:

- Full fill cavity wall applications

- Brick And Block Cavity Wall applications

- Rendered Dense Block and Block Cavity Wall applications