85mm Celotex Cavity Wall Insulation

Celotex Cavity Wall 85mm – an insulation material made from Polyisocyanurate. Polyisocyanurate – is a thermoset plastic typically produced as a foam and used as rigid thermal insulation. The PIR core is bonded to low emissivity foil facings on each side. Low emissivity foil facing provides improved thermal performance in sealed cavity air spaces, improving the achievable U-value.

Celotex is a much-trusted brand because of its durable and reliable high-quality products.

Thermal – 85mm Cavity wall boards have a thermal conductivity of just 0.022W/mK. To sum up, the thermal conductivity means less heat will pass through the insulation boards, keeping internal temperatures level.

Sustainable – The thermal properties of the Cavity wall board will also prevent heat / energy escaping the building and save money on energy bills. Less energy escaping will also create a more energy efficient property. In short, this will contribute towards the fight against climate change.

Celotex Cavity Wall Boards 85mm – The most used thickness when it comes to insulation materials, and it is easy to handle and install.

Key Features of Celotex Cavity Wall Board

- Lightweight

- Great thermal qualities

- More temperature controlled internal climate

- Energy Efficient and Sustainable

- Long lasting lifespan

- Durable and reliable

- Water repellent

- Easy to install

- Compressive strength: 120kPa

- Free from harmful gases (CFC and HCFC)

- They do not add to the formation of any gases with Ozone Depletion Potential (ODP) or Global Warming Potential (GWP)

85mm Celotex Cavity Application

Celotex cavity wall boards are rigid foam formed into rectangular shape designed for easy installation within partial fill, masonry cavity wall applications. In addition, the 85mm shape and size means there is little cutting required. The 85mm thickness and 1.2m x 0.45m size is a standard board and as a result can be installed in between wall ties.

The boards are extremely durable and last lasting. The 85mm Celotex Board will last for as long as the building does, and product performance will not reduce over time. The 85mm is a well-used product within the construction industry.

Store the Celotex Cavity Wall boards 85mm, stacked, on a flat surface. In addition, if indoor storage is not an option, use the correct weather proofing materials. In short, do not leave Celotex Cavity boards exposed to the elements because it can affect the performance of the board.

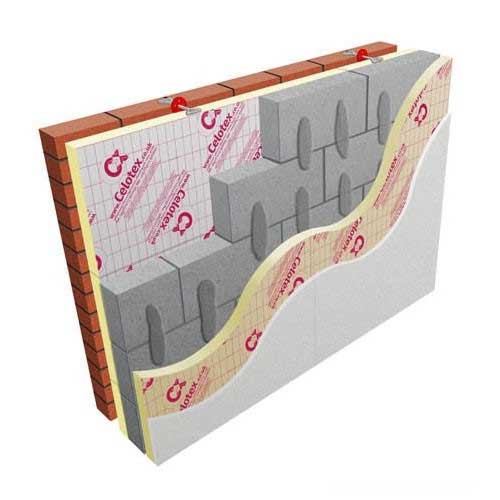

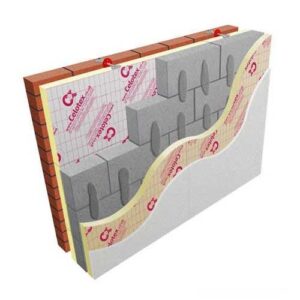

CW4000 is Cavity wall insulation which is made to be fitted in between the breeze blocks structure of the building (inner leaf) and the outside brickwork (outer leaf) to help insulate the building. The Cavity wall insulation must be fitted as you go when laying the inner and outer leaf.

How to Install Celotex Cavity Wall Boards

This is a guide only, always consult a building professional.

Step 1:

Firstly, Install wall ties into the inner leaf at 600mm apart horizontal centres

Furthermore, for suspended timber floors, wall ties start a minimum of 200mm below the top surface of the ground floor perimeter insulation upstand. Place the cavity tie clips (wall ties) 900mm apart.

After that, continue constructing the inner leaf up to the next wall tie course. (450mm above the previous inner leaf). Next, position the next course of wall ties at regular horizontal centres. Position extra wall ties at jambs for openings. Install the next course of blockwork secure the ties in place.

Furthermore, ensure excess mortar is cleaned away as you go.

Step 2:

Secondly, the first row of insulation boards should be installed between the two rows of wall ties (fleece must face outwards to cavity). In addition, retain each board tight against the inner leaf and but joints to get the best quality of insulation.

Always secure each board at a minimum of three points. Add additional ties to satisfy structural requirements such as around window frames or doors to ensure adequate retention of the Cavity Wall boards or cut pieces.

Step 3:

Thirdly, Apply a self-adhesive breathable tape to all horizontal and vertical joints of the cavity wall board edges and abutting junction interfaces. (No less than 85mm wide and no less than 50mm either side of any edge. add additional layers if needed.)

After that, build the outer leaf (outer brickwork) to the level of the top of the cavity wall boards and repeat the process. (Cavity of 10mm or less).

Finally, if finishing at a gable, continue cavity Wall insulation boards 200mm beyond the height of the top storey ceiling. Install a cavity tray above the insulation.

85mm Cavity Wall Board Certifications

- Euroclass E Reaction to Fire classification, according to BS EN 13501-1

- A+ rating in comparison to the BRE Green Guide 2008

- CE marking complying with BS EN 13165:2001

- BS EN ISO 9001:2000 and quality management systems

- Environmental Management System – ISO 14001:2015

| Dimensions | 1200 × 450 mm |

|---|---|

| Brand | Celotex |

| Thickness | 85mm |

| Material Type | Polyisocyanurate (PIR) |

| Pieces Per Pack | 16 Packs |

| Sales Unit | Pallet |

| Unit Coverage | 60.48m2 |

| Manufacturers Reference | CW4085 |

| Thermal Conductivity | 0.022W/mK |

| Density | 31.5kg/m3 |

| Fire Rating | Euroclass F |

| Edge Type | Square |

| Facing | Low Emissivity Foil |

| Weight (kg/m2) | 3.13kg/m2 |

| Product Range | Celotex Cavity Wall Board (CW4000) |

Ronald –

Could not get hold of enough sheets anywhere else!

Hubert –

This insulation material exceeded my expectations. Really easy to decorate

Dominic –

Wanted 75mm, made it work

Joshua –

was told by local supplier they have stopped making 85mm Cavity Boards, asked Trade Insulations who advised can do me a next day delivery

Charlie Griggle –

Used 85mm instead of 75mm, worked great.

Question –

is the thermal value the same as the 2400×1200 boards?

Peter Gabriel –

Celotex Cavity Boards are the only cavity boards I would bother with,I have used different brands over the years but not as good as Celotex.

Robyn Warren –

Driver was nice and helpful

Sally-ann Woods –

Really please with the service and delivery