| Dimensions | 2400 × 1200 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

150mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

2 |

| Sales Unit |

Pack |

| Unit Coverage |

5.76m2 |

| Manufacturers Reference |

K112150 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Composite Foil |

| Weight (kg/m2) |

5.66kg/m2 |

| Product Range |

Kingspan K112 Framing Board |

Please note this item is a Special Order – see terms and conditions

Kingspan Kooltherm K112 150mm Framing Insulation Board (2400mm x 1200mm) – 5.76m2 Pack

Request your delivery date in checkout

on orders over £350 +VAT

£402.00 Original price was: £402.00.£366.45Current price is: £366.45. ex VAT

In Stock

Please note this item is a Special Order – see terms and conditions

EXCELLENTTrustindex verifies that the original source of the review is Google. Great product for a great price. Order was processed quickly and delivered efficiently with care. Would definitely recommend.Trustindex verifies that the original source of the review is Google. A company where you can speak to someone if there is an issue and get it resolved efficiently.Trustindex verifies that the original source of the review is Google. Easy online transaction , good pricing and effortless delivery …. Agreed for item to be replaced if not in stock and replacement was sent … but no issuesTrustindex verifies that the original source of the review is Google. Very impressed with the delivery service. The driver dropped the materials exactly where I had requested, and everything arrived in perfect condition. Delivery was also much quicker than expected. Couldn’t fault the service – highly recommended!Trustindex verifies that the original source of the review is Google. Great experience. Product as described and delivered on time.Trustindex verifies that the original source of the review is Google. Highly recommended! Excellent service from ordering to delivery, thanks.Trustindex verifies that the original source of the review is Google. Great service thank you to James, who managed to get a pallet of rockwool to us in record time. Would recommend.Trustindex verifies that the original source of the review is Google. Very competitive pricing, excellent delivery. Would use againTrustindex verifies that the original source of the review is Google. Easy to order online. Good price and the delivery driver was very happy and helpful.Trustindex verifies that the original source of the review is Google. Great prices, great service.

Kingspan K112 150mm

Kingspan Kooltherm K112 is used between studs or as insulation sheathing in timber frame and steel frame walls. When installed in construction, Kooltherm K112 offers premium performance with a thermal conductivity as low as 0.019 W/mK.

Kingspan Kooltherm K112 has a rigid phenolic core and is faced on both sides with low-emissivity foil to provide low thermal conductivity. This makes this framing board insulation product perfect for new builds and refurbishment projects since it’s easy to install and handle. In a refurbishment project, this wall insulation can bring u-values even lower in areas where you previously might not have thought about insulating.

Resistant to the passage of water vapour, installing Kooltherm K112 as insulation sheathing can be a good idea to ensure other insulation types are kept safe and performing. This is also down to the fact that Kooltherm K112 isn’t affected by air infiltration.

The K112 Framing Board is made of a phenolic rigid board, which is bonded to low-emissivity composite foil facings on each side during manufacturing. This reflective, low surface enhances the thermal resistance of any unaired cavity adjacent to the board

This product provides excellent compressive strength and thermal performance. The board can have an indefinite lifespan, provided it is installed correctly. The boards are water resistant, which means they will prevent mould or rot from developing and microbial growth even if there is condensation in the installation area. Condensation can be controlled in areas containing Kooltherm K112. This is accomplished by ensuring there is a high vapour resistance on the warm side of the insulation layer. Vapour resistant is increased when vapour check plasterboards are added.

The core is also resistant to petrol and most dilute acids, alkalis, and mineral oils when in contact short term. It is recommended, should the boards come into to contact with any liquids, that they are cleaned off and left to dry asap. Guidelines should be read when using this product as particular solvent-based adhesive can affect the boards and should not be used, particularly those containing methyl, ethyl, and ketone. Damaged boards or boards that have been in contact with harsh solvents or acids should not be used.

By insulating your property, you are creating a more energy-efficient environment. This will also save you money on up to 75% of your energy bills as well as providing a comfortable temperature-controlled environment.

Certifications:

- ISO 9001: 2015 (Quality Management Systems. Requirements)

- ISO 14001: 2015 (Environmental Management Systems. Requirements)

- ISO 45001: 2018 (Occupational Health & Safety Management Systems)

- ISO 50001: 2018 (Energy Management Systems)

- BBA Certificate 16/5299.

- ISO 37301: 2021 (Compliance Management Systems)

- BES 6001 (Responsible Sourcing – Good)

Key Features

- Full fill cavity insulation

- Resists moisture penetration

- Unaffected by air infiltration

- Easy application

- High compressive strength

150mm K112

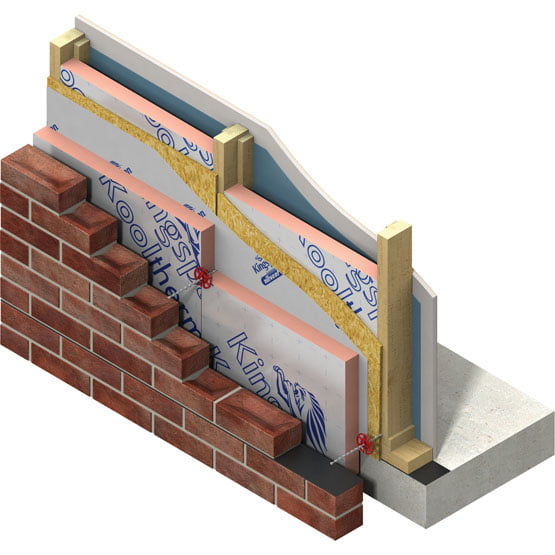

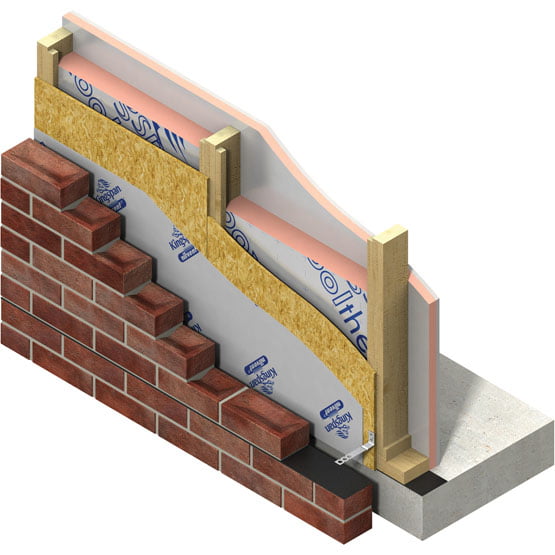

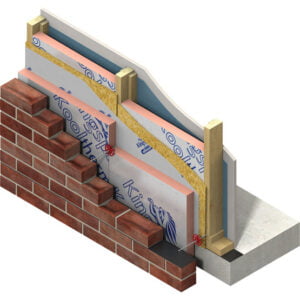

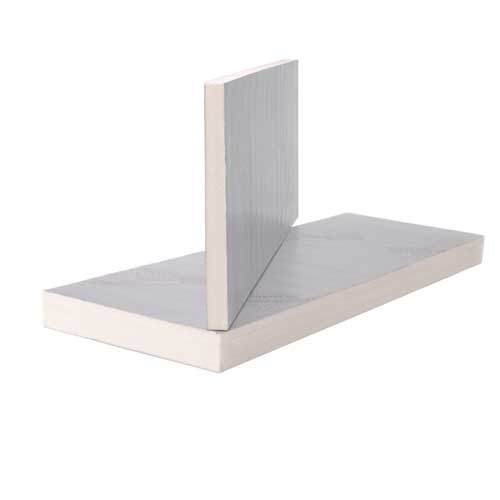

Kingspan K112 can be installed in a range of methods. These methods include:

- Insulation Between Timber Frame Studs with K118 Fixed Internally

- Insulation Between Timber Frame Studs and Insulated Sheathing

- Insulation Between Timber Frame Studs with K118 Fixed Internally

- Insulation Between Timber Frame Studs and Insulated Sheathing

- Insulation Between Timber Frame Studs with K118 Fixed Internally

- Insulated Sheathing on Steel Frame

- Insulated Sheathing on Timber Frame

| Dimensions | 2400 × 1200 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

150mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

2 |

| Sales Unit |

Pack |

| Unit Coverage |

5.76m2 |

| Manufacturers Reference |

K112150 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Composite Foil |

| Weight (kg/m2) |

5.66kg/m2 |

| Product Range |

Kingspan K112 Framing Board |

| Dimensions | 2400 × 1200 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

150mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

2 |

| Sales Unit |

Pack |

| Unit Coverage |

5.76m2 |

| Manufacturers Reference |

K112150 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Composite Foil |

| Weight (kg/m2) |

5.66kg/m2 |

| Product Range |

Kingspan K112 Framing Board |

Michael –

Efficient but expensive

Andrzej –

Wish I had found this company sooner with these prices

Chike –

The insulation was exactly as described, and the price was unbeatable

Samuel –

The driver was very polite, and customer service was quick to respond to my inquiries

Nombuso –

Thank you so much

Ryder –

Quick delivery

Karen –

A very professional team, delivery driver was great!

Angus –

thanks again to carl who give me a follow up call asking how it went

jennifer hill –

I called ahead of this order, the team helped with all of my questions and talked me through the website

Harry –

Excellent product – nice and lightweight and nice to work with. Website was easy to use and simple enough.

sarah clark –

Quickly installed and framing completed.