115mm K106

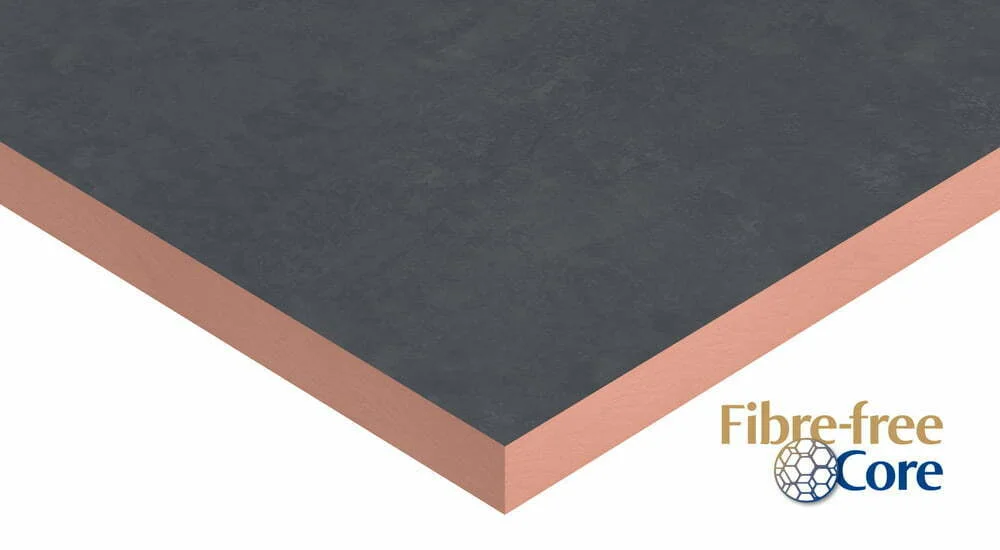

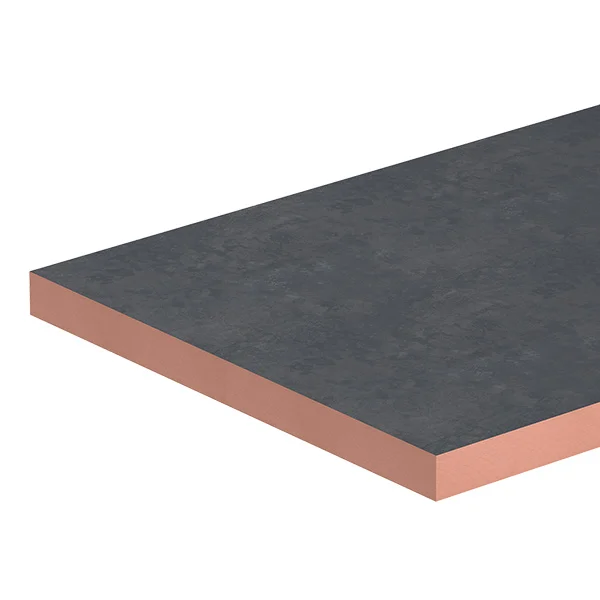

Kingspan K106 115mm is an insulation material manufactured with a phenolic core. The K106 Cavity wall insulation board has a thermoset fibre-free rigid phenolic core. The K106 board has a low emissivity composite foil facing on one side. The other side is bonded to a polypropylene fleece. As well as the 115mm board, the Kingspan K106 range offers a 90mm cavity wall board.

Polypropylene Fleece – Polypropylene is a rigid, semi-crystalline thermoplastic. Used widely today in a range of domestic and industrial applications. Polypropylene sheets are a tough, lightweight plastic that offers low water absorption. The sheets hold excellent resistance to acids, alkalis, and organic solvents. Polypropylene is a great material to pair with insulation materials due to its long-lasting and durable nature.

Thermal – K106 has a thermal conductivity of just 0.019W/mK. The thermal conductivity means less heat will pass through the insulation boards. As a result, this will keel internal temperature level. The thermal properties of the K106 115mm will also prevent heat and energy escaping the building and because of this the building will be a much more comfortable space.

Sustainability – The K106 cavity wall board will help by reducing the heat levels lost through the building. This will reduce the contribution to global warming and in conclusion, have positive effects on climate change. Moreover, the lack of heat loss can save money on energy bills up to 30%.

Resistance to solvents, fungi & rodents – The board is resistant to short-term contact with most dilute acids and other fluids. Clean spills off before the boards are installed. Do not used damaged boards with long contact to harsh solvents. K106 boards resist attack by mould and microbial growth. The boards core does not provide food value to vermin.

Key Features of 115mm Kingspan K106

- Lightweight as well as easy to cut, handle, and install

- Great thermal qualities

- Temperature-controlled internal climate

- Saves money on monthly bills

- Long lasting lifespan

- Durable and reliable

- Free from harmful gases (CFC and HCFC)

- They do not add to the formation of any gases with Ozone Depletion Potential (ODP) or Global Warming Potential (GWP)

- Full fill cavity insulation

- Resists moisture penetration

- Unaffected by air infiltration

- Non-deleterious material

115mm K106 Cavity wall insulation is 1200mm x 450mm with a thermal conductivity of 0.019W/mK.

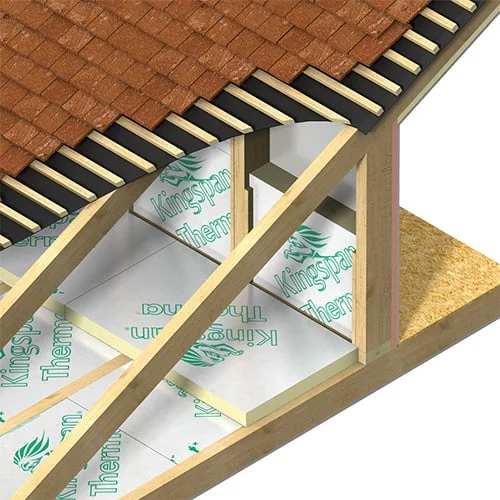

115mm Kingspan K106 Application

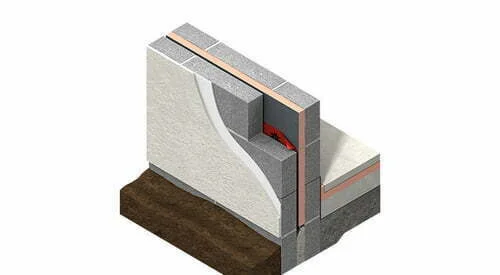

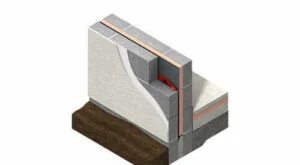

K106 115mm boards are a rectangular shape. These boards are designed for easy installation. The K106 cavity wall boards are for full fill cavity wall insulation applications.

The 115mm is a board designed for a specific application and most importantly, the K106 boards need to be installed whilst the walls are being built. The multi-purpose boards are designed for commercial, residential, and industrial buildings as well as new builds and refurbs. In addition, K106 can help to meet building regulations.

The boards are extremely durable and last lasting. In addition, the 115mm Cavity wall board will last for as long as the building does. The product performance will not reduce over time. Therefore, the K106 115mm is a well-used product within the construction industry. Moreover, the thicker nature of the 115mm board means this board gives the best quality thermal protection because of its higher R-value.

How to Install K106 115mm Cavity Wall Boards

Cut K106 cavity boards using a fine-toothed saw or a sharp knife. Use the sharp knife by scoring and snapping the boards and scoring the other side.

Always consult a building / construction professional before insulation your property because this can be a costly and time effective mistake. Ensure the walls are free from condensation and mould before insulating. Please note this is a guide only.

Firstly, install wall ties in the inner leaf at 600mm horizontal centres. Secure each board with three wall ties. Continue to construct the inner leaf up to the next wall tie course. secondly, position the next course of wall ties at regular horizontal centres. After that, position extra wall ties at jambs for all openings. The next course of blockwork will secure the ties.

Remove excess mortar and mortar droppings as you go. The next course of wall ties is positioned at the usual 900 mm horizontal centres. The next course of blockwork is installed to secure the ties.

Thirdly, apply a self-adhesive breathable tape to all horizontal and vertical joints, board edges and abutting junction interfaces. These surfaces should be clean, dry and free from grease, dust, and dirt prior to application.

Fourthly, build the outer leaf to the level of the top of the boards. After that, repeat the process. (Cavity of 10mm or less). See installation video here –

K106 Certifications

- ISO 9001: 2015 (Quality Management Systems. Requirements)

- ISO 14001: 2015 (Environmental Management Systems. Requirements)

- BS OHSAS 18001: 2007 (Occupational Health and Safety Management Systems. Requirements)

- BS EN ISO 50001: 2011 (Energy Management Systems. Requirements with guidance for use)

- The Harmonised Standard BS EN 13166: 2012 + A1: 2015 (Thermal insulation products for buildings. Factory made phenolic foam (PF) products. Specification)

| Dimensions | 1200 × 450 mm |

|---|---|

| Brand | Kingspan |

| Thickness | 115mm |

| Material Type | Phenolic |

| Sales Unit | Pack |

| Unit Coverage | 2.16m2 |

| Manufacturers Reference | K106115 |

| Thermal Conductivity | 0.019W/mK |

| Density | 40kg/m3 |

| Fire Rating | Euroclass F |

| Edge Type | Square |

| Facing | Polypropylene Fleece |

| Weight (kg/m2) | 4.6kg/m2 |

| Pieces Per Pack | 4 |

| Product Range | Kingspan K106 Cavity Board |

Zanele –

Does exactly what it claims to do. Ordered for our contractor, my home feels much more comfortable now.

Nathaniel –

Really swift delivery

Amina –

Excellent service, great comms and fast delivery

kyle –

Want to thank Jeff who dropped the goods off

Kamau –

All arrived on time without any issues.

Razvan –

Quick delivery