Storage containers – also known as shipping containers – are generally used for basic storage needs and to ship goods worldwide. Companies such as Container Storage Essex specialise in providing insulated storage using shipping containers. Another new, more common form of purpose for a storage container is to transform the area into a unique workspace or a quirky home conversion. The containers offer an alternative and cost-effective solution to the rise in property values and rent fees. To use storage containers as a living or working space the appropriate applications such as flooring, walls and insulation will need to be applied to create a fully functioning residential or commercial space. Containers bake in hot climates and freeze in cool climates because heat moves easily through steel. The insulation materials will also help to reduce noise, create a more energy-efficient space and will help to reduce energy bills.

What is insulation?

Insulation is a material used specifically to improve a properties thermal conductivity. Insulation materials are generally manufactured using either mineral wool (which comes packaged in a slab or roll) or polyisocyanurate (PIR) (which comes in sheets or slabs). The materials are applied to the envelope of the property – walls, ceilings, floors, and roofs – to create a more temperature-controlled environment. Insulation will keep the heat out during the summer and the cold out during the winter. It also works both ways by preventing hot or cold air produced from within your property such as heating or air conditioning from escaping.

Insulation is available in a range of brands, sizes, and thicknesses to suit specific project needs. Our most popular brand of insulation is Celotex

120mm Celotex Insulation Board – XR4120 (2400mm x 1200mm x 120mm) 2.88m2

Original price was: £51.99.£35.85Current price is: £35.85. ex VAT75mm Celotex Insulation Board – GA4075 (2400mm X 1200mm X 75mm) 2.88m2

Original price was: £34.99.£23.86Current price is: £23.86. ex VAT90mm Celotex Insulation Board – GA4090 (2400mm x 1200mm x 90mm) 2.88m2

Original price was: £42.95.£29.28Current price is: £29.28. ex VATCelotex 100mm PIR Insulation Board – GA4100 (2400mm x 1200mm x 100mm) 2.88m2

Original price was: £39.99.£29.25Current price is: £29.25. ex VATInsulating a storage container

There are several ways a shipping container can be insulated. These options include applying insulation materials or spray foam. Before choosing your insulation material and application method, there are a few things to be considered including the location of your container.

If the container is located in an environment with colder weather conditions, thicker insulation materials will be required to create a higher thermal quality.

Another factor to be considered is what the container is being used for. Home conversion spaces will need insulation materials that will provide warmth and comfort for longer periods of time in comparison to an office space that won’t need to be used for lengthy periods of time such as through the night.

Containers are made up of steel which can be heavily affective by extremely hot or cold weather conditions. Condensation can allow mould to form and over time which can cause the container to corrode, the correct insulation will need to be applied to prevent rot occurring.

Insulation a storage container can be expensive however insulating your storage container yourself to save money is an option.

Types of insulation materials to use for a storage container

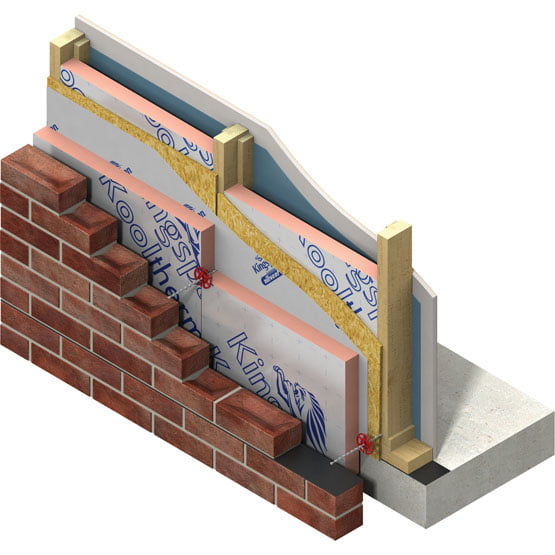

Most materials with insulating properties can be used to insulate a storage container. Rockwool and Kingspan are the most effective and popular insulation materials for storage containers. Both products will need to have a timber frame installed to keep the insulation in place, the stud wall will then be covered with either plywood or plasterboards depending on usage.

Realistically any material with insulating properties can be used to insulate shipping containers. This offers scope for anyone wanting to recycle or re-purpose other materials in their container conversion.

Rockwool

Rockwool insulation materials are extremely cheap and providing it is installed correctly, it will perform very well last and have a life span for as long as the containers. This is an everyday insulation choice when undertaking office conversions and similar. Although it performs extremely well and is affordable, when creating a home transformation as opposed to an workspace a higher grade insulation material would be recommended.

ROCKWOOL Flexi – 1200 x 400 x 100mm – 86.4m2 pallet

Original price was: £999.07.£832.56Current price is: £832.56. ex VATRockwool RW3 100mm Acoustic Insulation Slab (1200 x 600mm) – 2.88m2 pack

Original price was: £41.63.£34.69Current price is: £34.69. ex VATKingspan

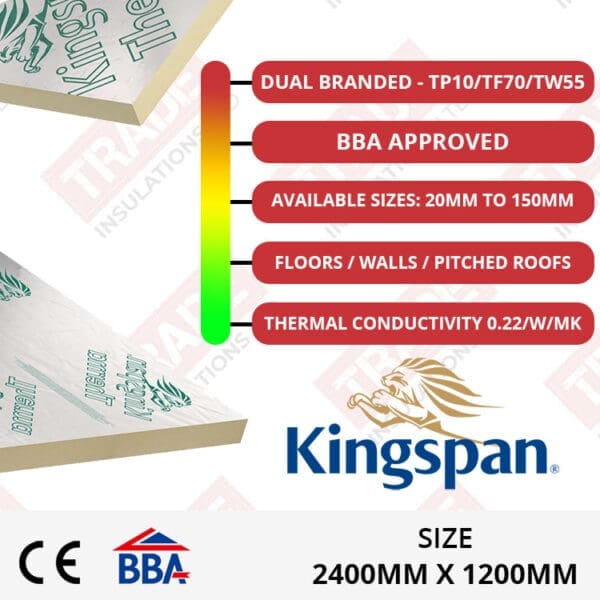

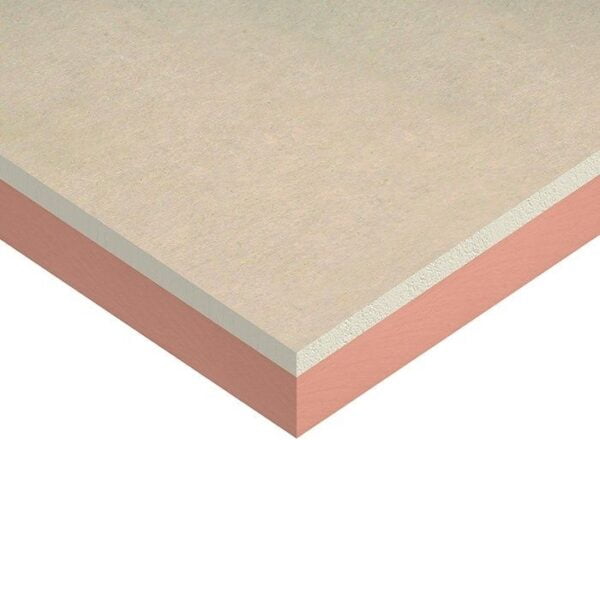

Kingspan is another type of insulation that can be installed within the container and then covered with ply or melamine boards. Kingspan is a high quality more expensive choice of insulation materials. This product will provide thinner products with the great thermal properties allow you to maximise space within your container but keep it warm.

100mm TR24 Kingspan Thermaroof PIR Flat Roof Insulation Board (1200 x 600mm x 100mm) – 3.6m2 pack

Original price was: £119.90.£112.93Current price is: £112.93. ex VAT110mm Kingspan TP10 Thermapitch PIR Insulation Board (2400 x 1200mm) – 8.64m2 pack

Original price was: £230.26.£179.86Current price is: £179.86. ex VATKingspan Kooltherm K112 100mm Framing Insulation Board (2400 x 1200) – 8.64m2 pack

Original price was: £411.00.£363.42Current price is: £363.42. ex VATKingspan Kooltherm K118 37.5mm Insulated Plasterboard (2400 x 1200mm) – 2.88m2

Original price was: £78.59.£65.49Current price is: £65.49. ex VATSpray Foam

Spray Foam is also an option that seems very popular within international container home and office transformations. Spray foam is a method of insulation that provides quick application and a seamless vapour barrier; however, it is a more expensive option. Spray foam performance levels are still debateable however, it will work at least as well as any other insulation material.

How to insulate a shipping container – step by step:

Step 1: Apply a layer of weatherproof material to all surfaces of the container. Weatherproofing materials can also be applied to the outside of the container to help provide weatherproof conditions.

Step 2: Create an internal timber frame – like a stud wall – inside the container on each wall. This will create the foundations for the internal wall (this may be using plywood in a basic storage container or plasterboard in a home conversion).

Step 3: Your chosen insulation material can then be cut to size and used to fill the cavity between the internal wall frame and the metal of the container. The cavities between timber frame battens should also be filled with the chosen material.

Step 4: Plywood or plasterboards should then be cut to size and applied to the timber frame using the required fixings.

Step 5: Complete the wall with the necessary products such as corner beading or joint tape and continue to decorate with either plaster, wallpaper, or paint.

The same method can be used to apply ceiling insulation.

Install a timber frame onto the ceiling, fill cavities with the chosen insulation materials and cover with plywood or plasterboard using the appropriate fixings.

Notes:

- Always consult a professional before applying insulation to your living or working space. Installing the incorrect insulation materials can be a very cost effective and timely mistake to make.

- Ensure you have made the outside of your storage container weatherproof by diverting water away from the container. This included the roof and underneath the container. Water can cause steel to rust ruining you home of office space.

- Do not use conventional insulation methods unless they are corrosion-resistant or resistant to condensation. Most houses are traditionally insulated on the inside with fiberglass or wool. If you apply this concept to container homes, the result may lead to the material’s corroding or too much condensation inside the walls due to too much moisture, heat, or fumes.